The X-20 18mm RC Rocket glider kit is based on the proposed Air Force single man Shuttle concept. Construction is very simple and takes about an hour and a half. The kit includes pre-hinged control surfaces, pre-installed spar and pre-cut 6mm depron parts. Kit includes rail buttons. Length 23″, wingspan 15″, weight 5.7 oz rtf. It uses a profile construction to maximize wing area to give the best possible glide. Please refer to the General information for all kits tab above, then read these instructions completely before starting assembly. For 18mm D2.3T and C3.4T reloadable rocket motors only.

CG location for rocket flight: 8” forward of the rear end of the motor tube with battery and motor installed ready to fly.

Unpacking your kit:Carefully slit the tape holding the cardboard sandwich around the foam and gently remove the sandwich from the box, then gently trim the tape holding the top piece onto the bottom piece, should be four pieces of tape. You can then see the foam wrapped in plastic. It’s wrapped pretty well, it will take some time to gently cut with an exacto to remove the plastic wrap, don’t pull on anything or you may crack something, I know it’s a pain but it’s the only way I could make sure they were secure in shipping. There are little foam pieces, don’t lose them, the parts baggie was heavy so is well taped. The spars are taped to one of the cardboard pieces. Kits contain one or two scrap pieces for repairs if you damage anything in construction or flight, just cut and patch in a spare piece of the foam if needed using foam safe CA+.

Welcome to the world of rocket boosted radio control gliders. This is not a model for a novice RC pilot, but anyone who is comfortable with RC flying of a medium speed model should be fine. Read through the instructions, look at the photos and be sure you understand the step before committing to cutting or glue.

Identify all pieces, the kit should contain:

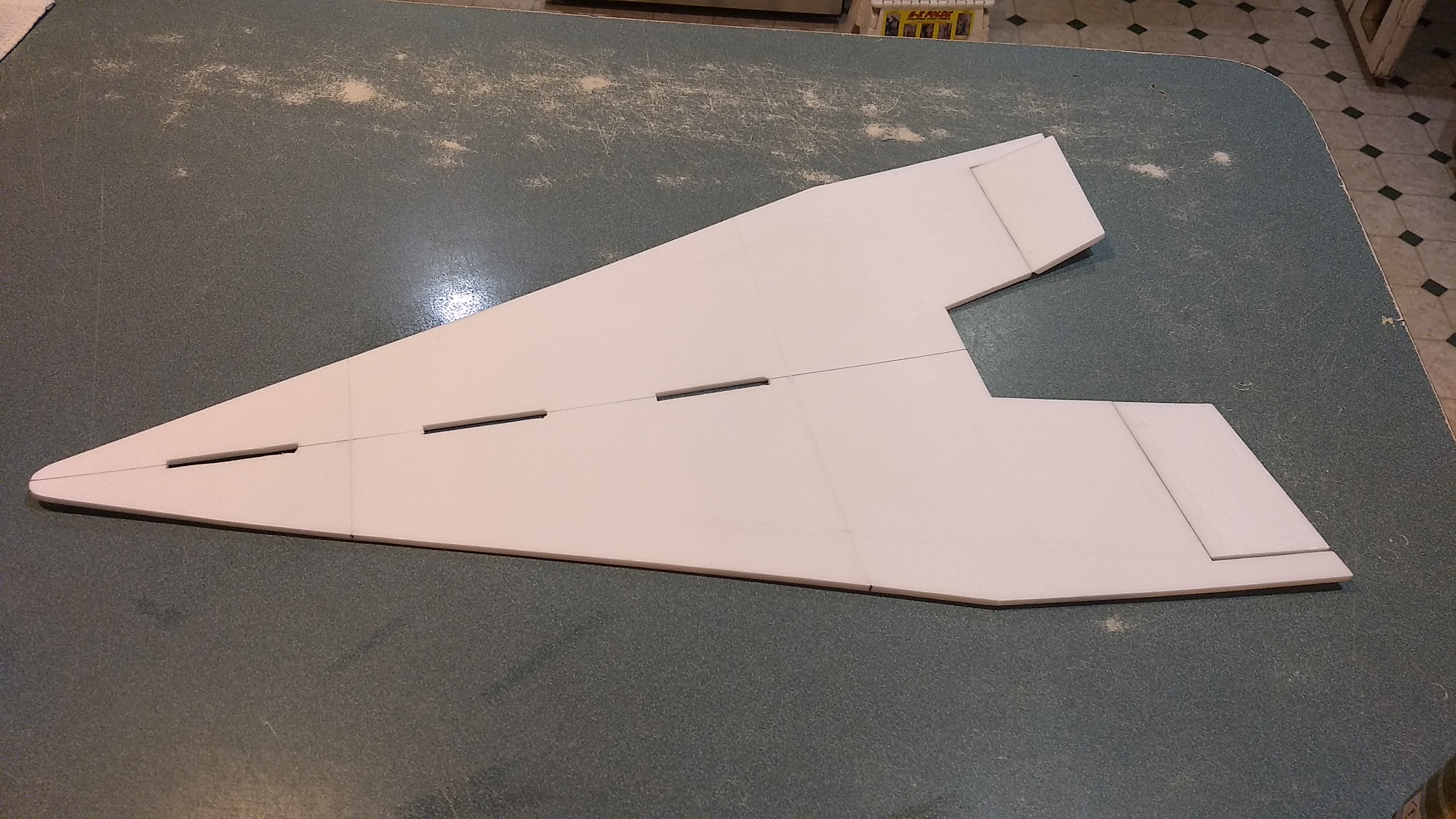

1 wing taped together 6mm

1 Fuselage Side view 6mm

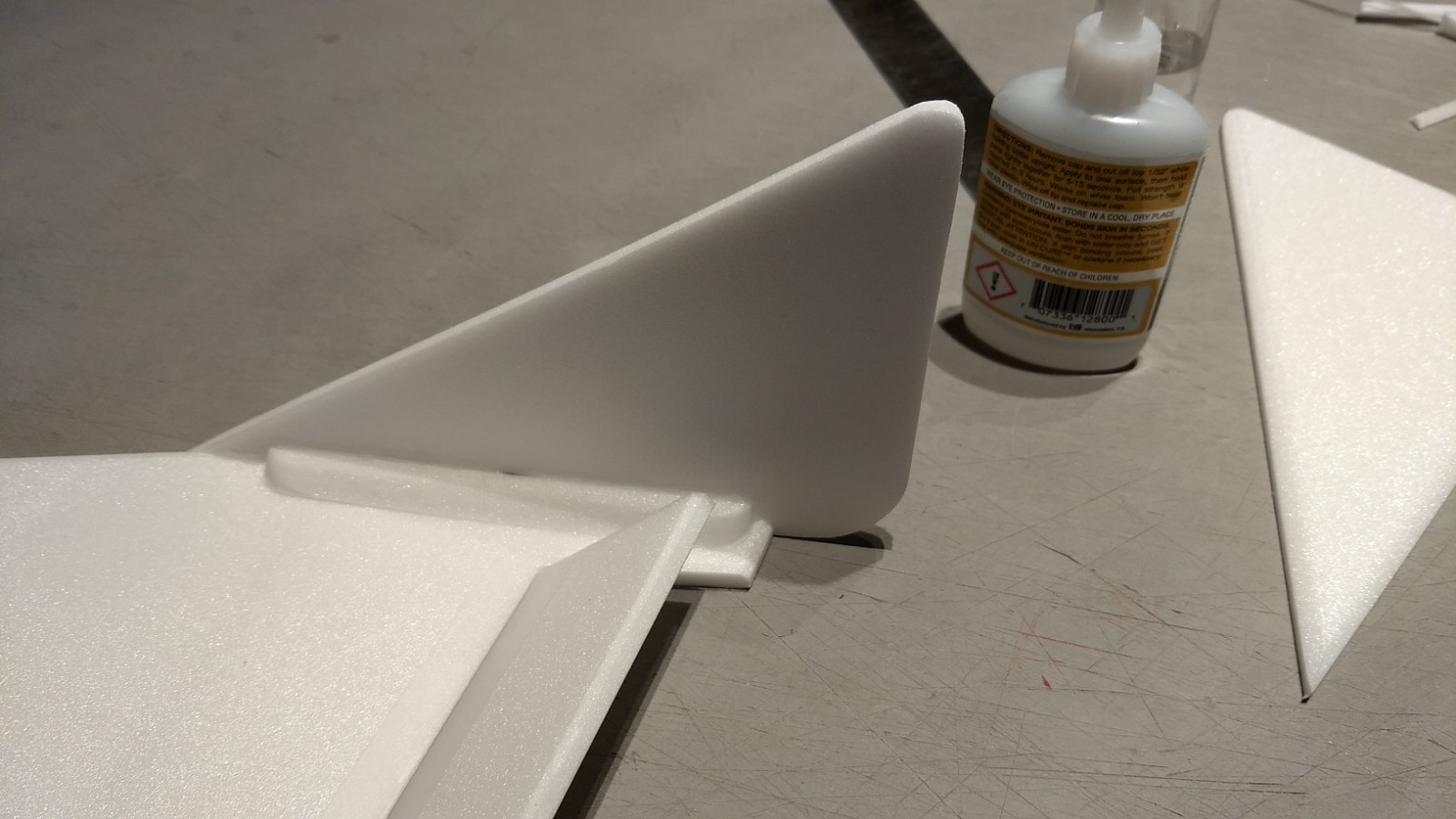

2 vertical stabilizers 6mm

2 5″ long stabilizer gussets

2 3″ long bottom forward fuse nose weight dams

2 control horns/Pushrods

2 sets of styrene disks, rail buttons and screws.

Motor mount

Velcro(for battery and rx/bec attachment)

Lead weight

Blenderm tape

Notes before starting:

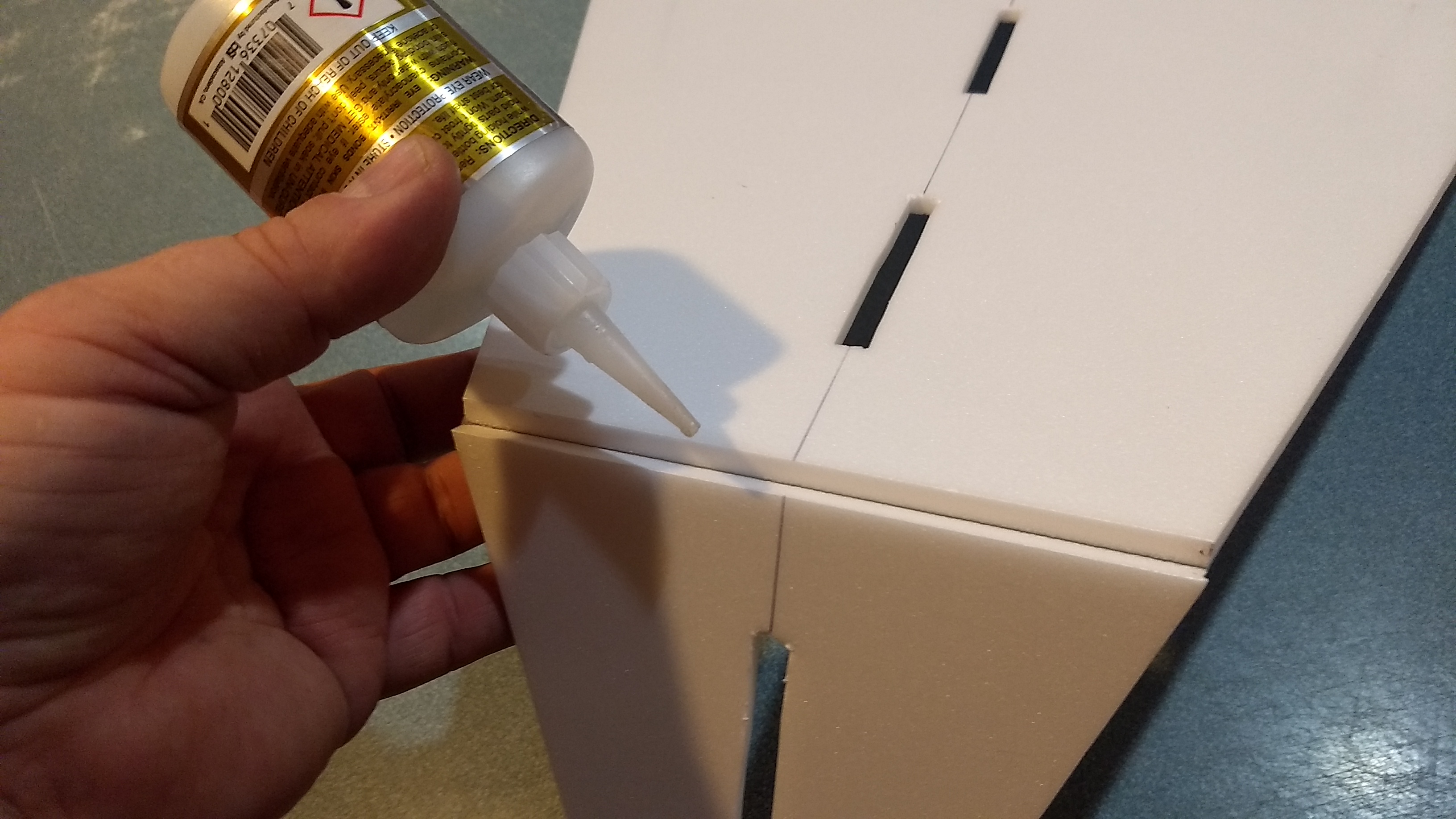

Foam safe CA+(Bob smith super gold + is good) is the only glue recommended for construction. You will also need foam safe accellerator to set the glue. Epoxy is only used for securing the lead weights to the model at the front where weight is needed.

I’ve found it’s better to use a straight edge and sharp exacto to do a 1/8″ bevel cut on the edges of the wing/stabilizers instead of trying to sand them round. For the few steps that require sanding below use a hard sanding block and 320 grit paper and go light and take your time.

Assembly:

- Unfold the wing and use foam safe CA+ to glue the two taped joints, use accelerator to set the glue.

- At this time I would bevel the leading edges and trailing edges of the wing and elevons, I just beveled the top edge about half way and left the bottom edge alone. Don’t bevel the wing tips where the vertical stabs will go, those edges need to stay square.

- Lightly bevel the fuselage top view just to break the edge slightly. Just bevel the top edge, not the edge with tabs.

- Make a left and right vertical stabilizer, bevel only the outside leading, trailing and bottom edges, the inner edges need to be as cut.

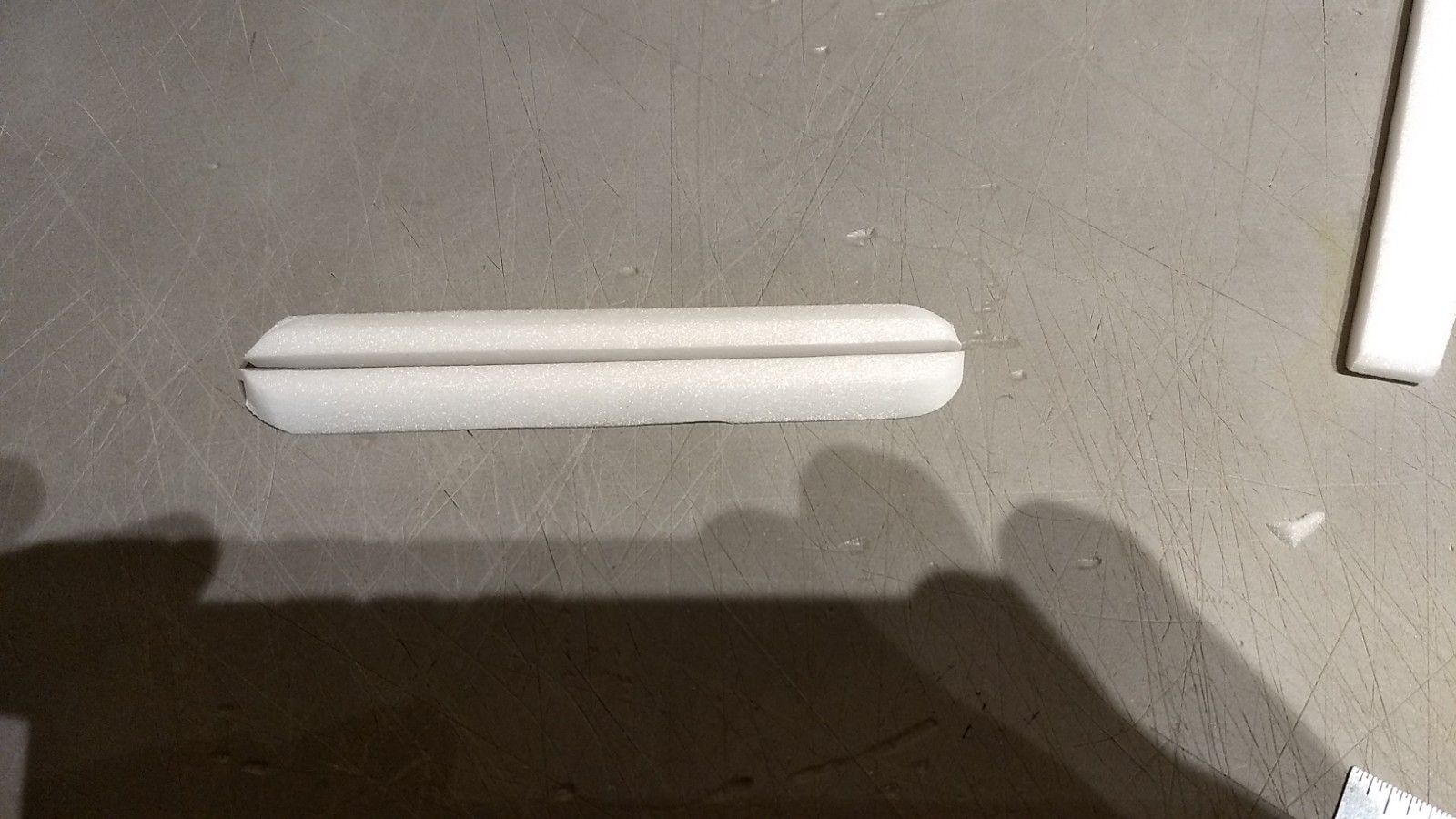

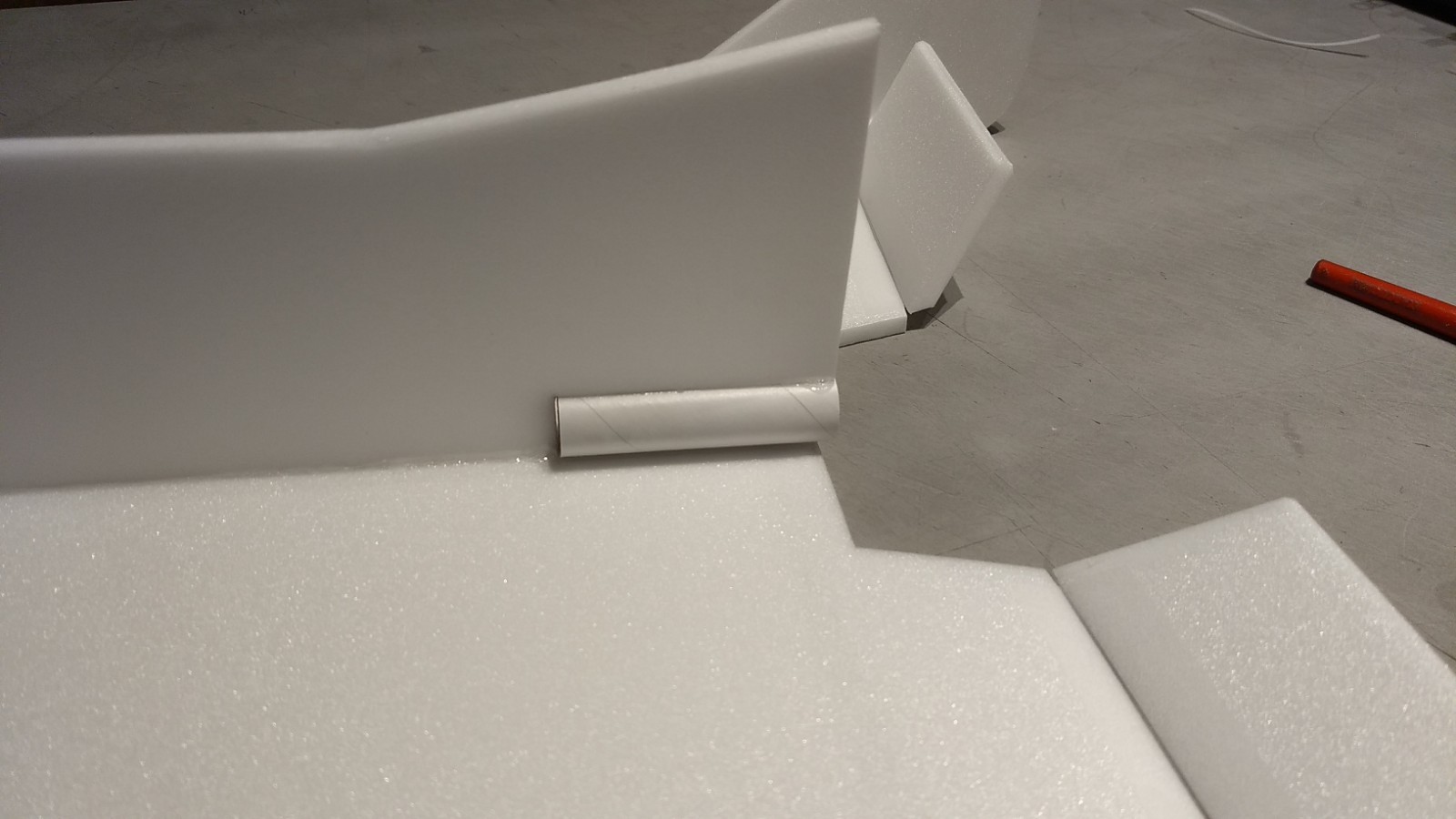

- Round the front and rear of each 5″ long reinforcing gusset strip, then glue one to each wingtip, centered and with the flat face facing the wing tip, this adds area for the wing tip to glue to. Dress the wingtip/gusset slightly to make sure it is flat before proceeding.

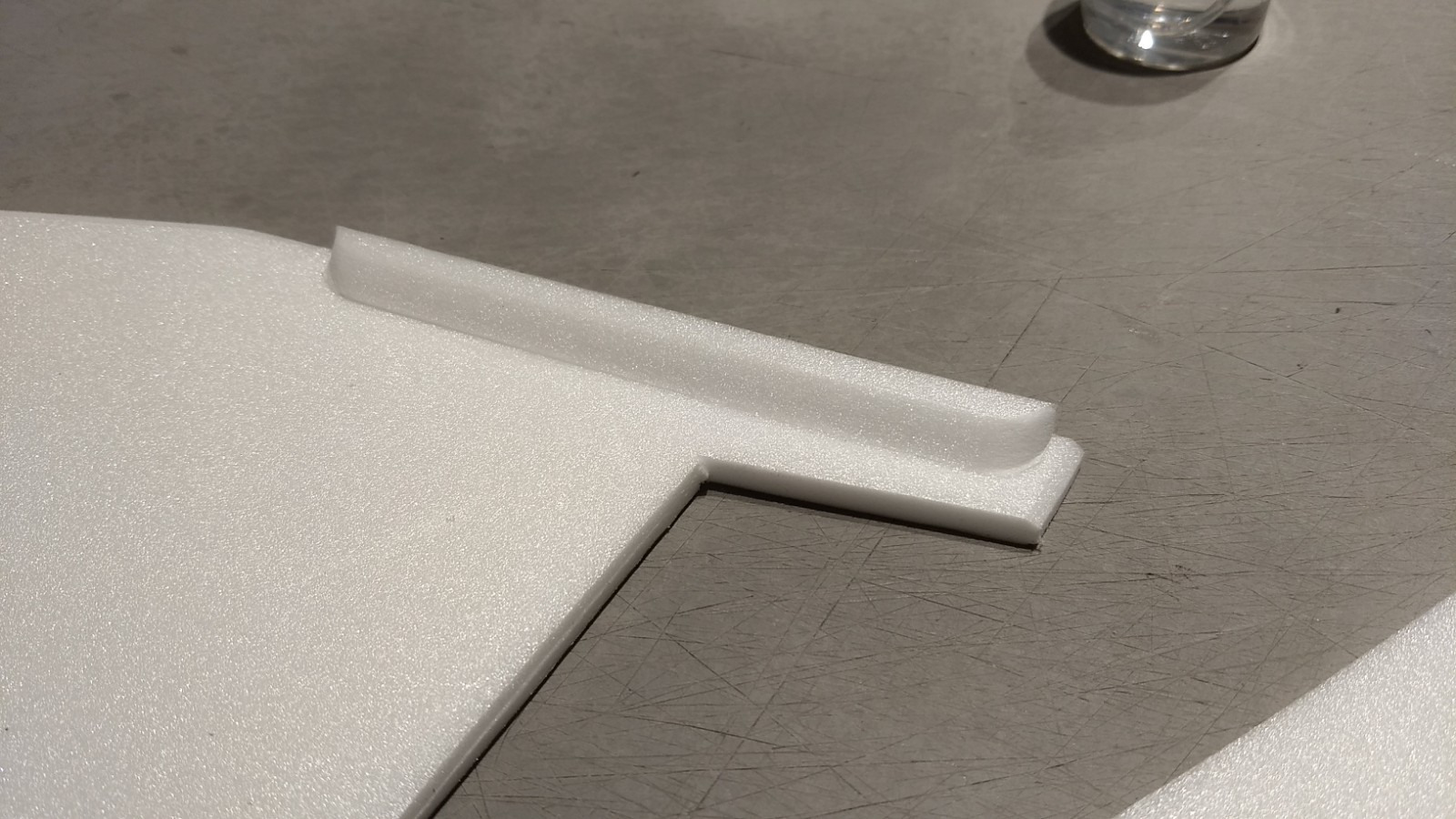

- Put some wax paper under each wingtip then glue each vertical stab onto each wing tip, the pointy front of the stab will be flush with the front of the wing tip, the rear rounded portion will stick back past the elevon.

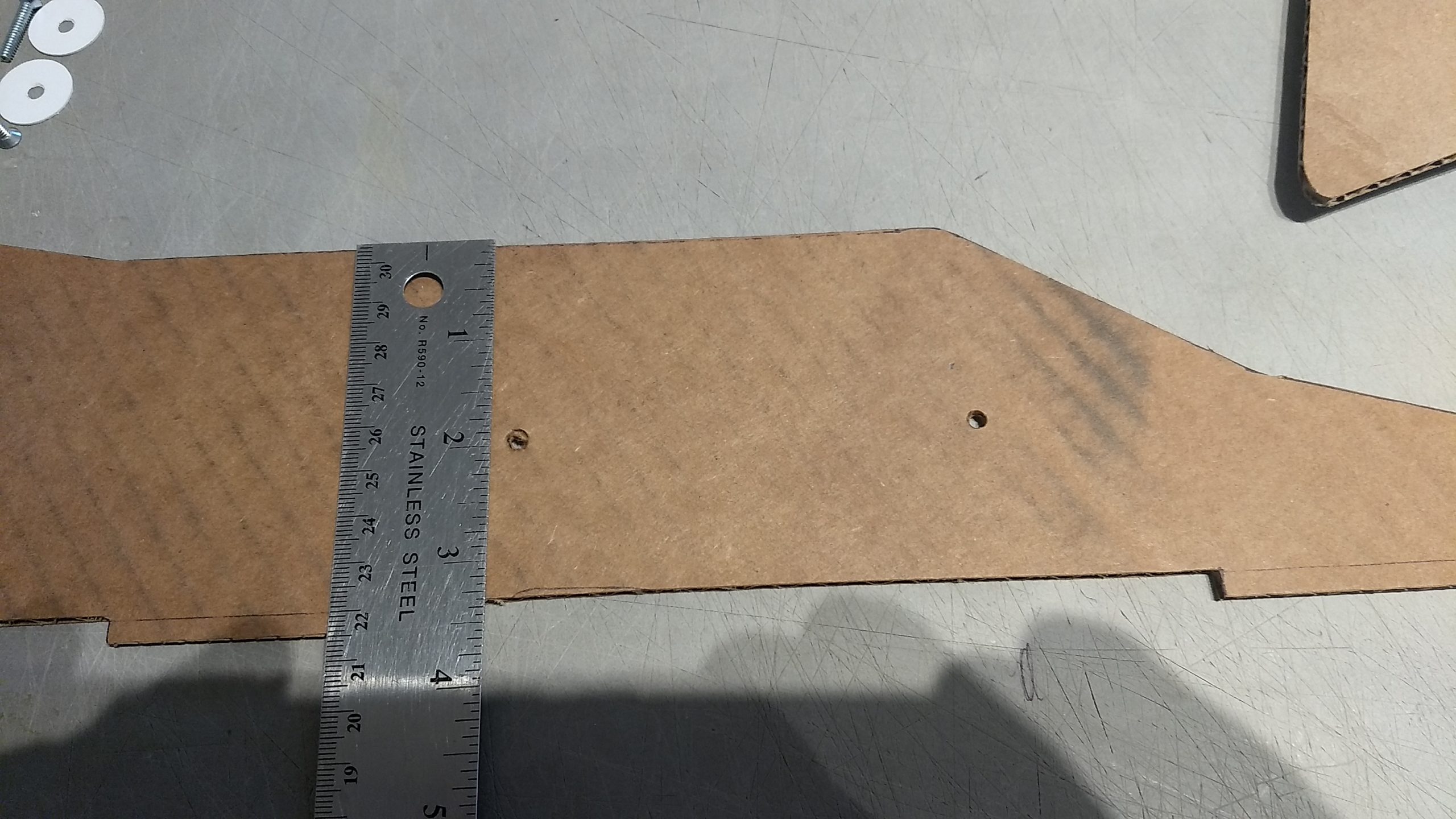

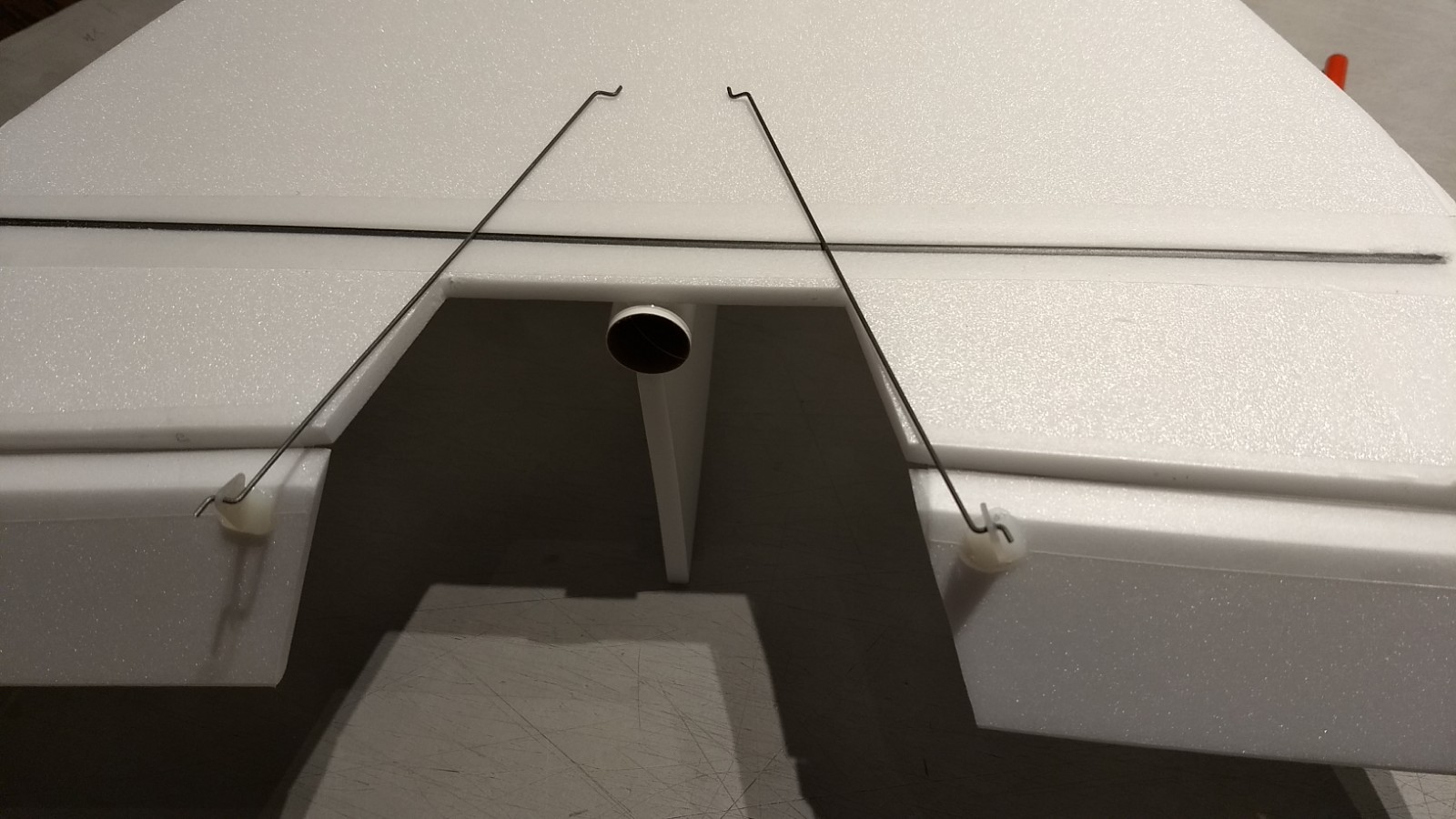

- If your kit is not marked for the rail buttons in the fuselage side view piece, mark two holes, one 8″ from the rear of the piece and 2″ down from the top, and a second 4″ forward of that hole.

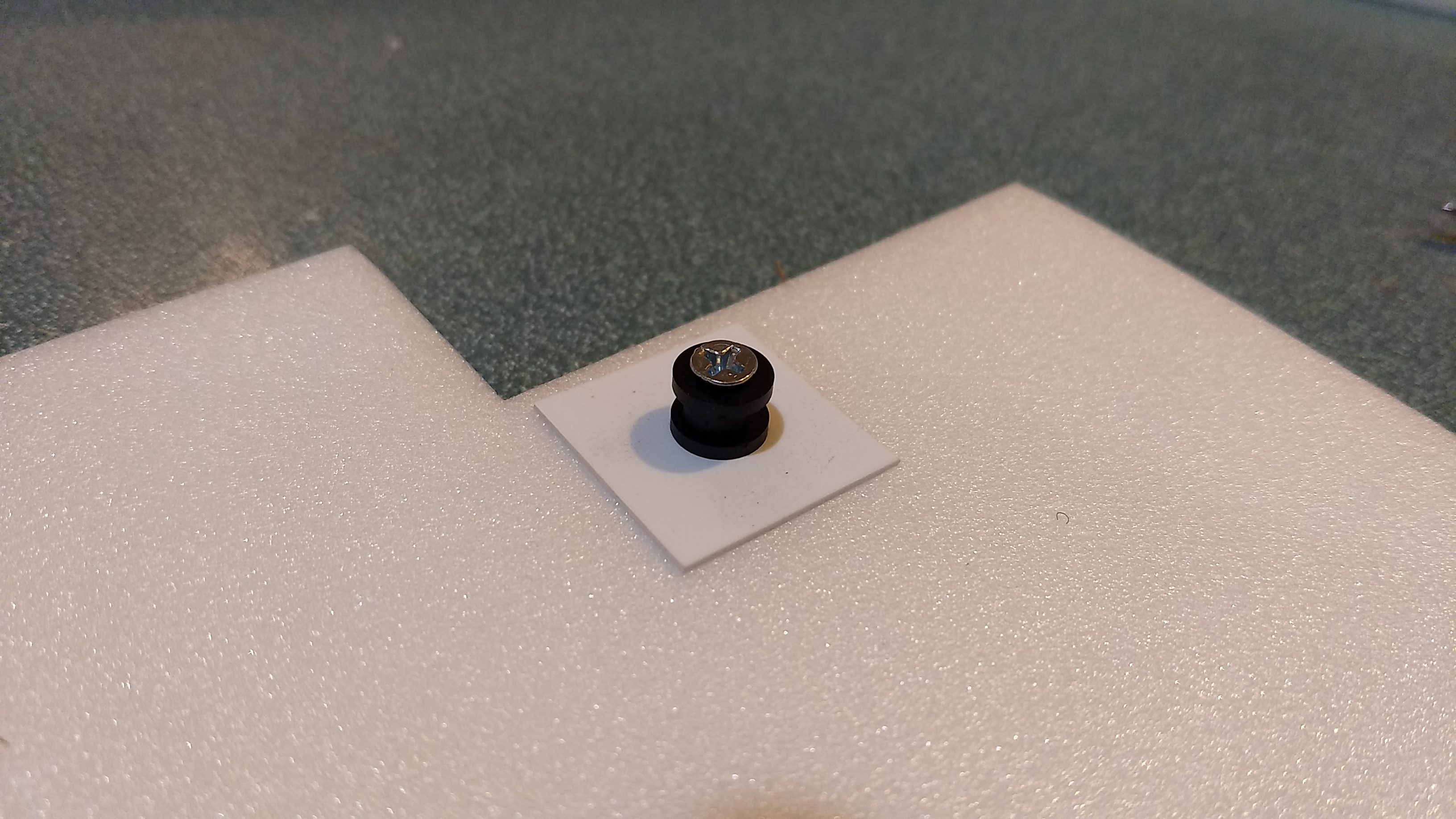

- Glue a styrene reinforcing disk onto the fuselage side centered on each of the two holes. These support the rail buttons. Repeat on the other side.

- Insert a T-nut from one side into each of the plastic styrene pieces, then install the rail button and screw onto the other side. These are located so that the rail should not interfere with anything on the model.

- Test fit the upper fuselage into the slots in the wing, then glue it in place making sure the wing stays flat and the rear is straight.

- Glue the motor tube centered in the notch at the rear of the fuse and against the top of the wing. Make sure it is centered and straight then glue in place.

- Glue the two 3″ long bevel cut foam pieces on the bottom front of the nose, sand where they meet at the front before gluing. This creates a dam to hold the lead nose weight in place when you add it.

- Sand the nose to a pleasing round shape.

- Glue a pushrod/control horn into each pre-made set of holes in the bottom inboard edge of each elevon. I mount them so that the pushrod is closest to the fuselage side so that the pushrod angles in slighty at a natural angle so the servo is closer to the fuselage.

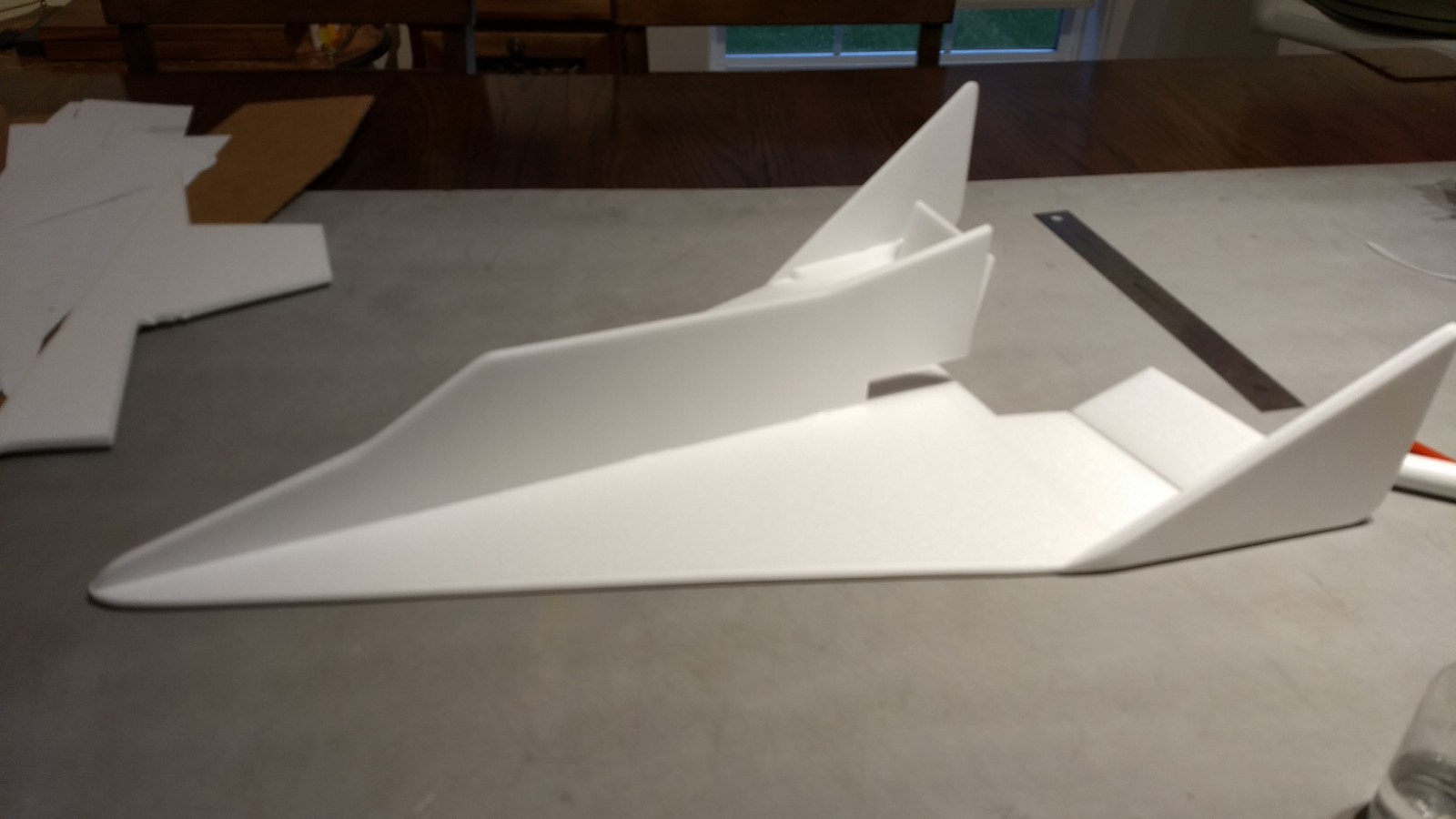

The basic construction is now complete.

Radio Installation

Note: Your radio needs to be configured for Delta mixing, this means that the servo arms will move the same direction during elevator stick movement and opposite for aileron stick movement. Connect your servos to the receiver one in the aileron connection and one on the elevator connection and apply power. Use a servo arm at least 9/16” long and with holes small enough that there won’t be slop with the pushrod wire when installed. I use the hole furthest out on the servo arm, to maximize movement. On some servos there are a long two-ended servo arm, you can trim off one end and use that arm to get sufficient length. Zero out any trim settings on the transmitter.

- Flip the model upside down. Connect each servo to a pushrod. If the pushrod is too tight, you can use twist an X-Acto knife in the servo arm hole to make it larger, but be careful and do not make it too large. Each servo should be on the bottom of the wing, with the servo electrical wire pointing forward and the servo arm pointing toward the wing tip. Tape each servo in place so that the control surfaces are centered With the model right side up look at it from the rear. Moving the transmitter stick back(up elevator) should move both elevons up. Moving the transmitter stick to the right should move the right elevon up and the left elevon down. If you can’t get the servo reversing to give you the right polarity try swapping aileron/elevator inputs to the receiver or turning the servos over and swapping the servo arms to the other side of the output shaft. If that is correct, continue.

- The servos are attached to the model with foam safe CA+. With the radio still on, put a moderate amount of glue on the servo, being careful not to get any near the output shaft, and set it in place on the wing keeping the control surface centered. Do the same to the other side. Make sure the glue is set before continuing. Note** The servo wire should point toward the front of the model. Apply a fillet of glue around the servo/wing to help secure it and let it cure being careful not to get any glue near the output shaft of the servo. Make sure you don’t try to glue the servo to any taped areas as it won’t stick.

- Make sure the control surfaces are centered, use trims if needed. Now measure the control surface movement. Full elevator movement should be 1/2″ and aileron movement 1/4″ When setting the control surfaces for neutral use the middle of the wing as your guide for what is level.

- If you have a flap/elevator mix you can program up elevator trim for boost and glide. If you can’t set the up elevator trim to a switch on your radio you’ll have to manually put in boost and glide trim using the trim tabs which is hard to do while flying the model. My model needed about 1/16″ of up trim for vertical boost and approximately 3/16-1/4″ of up trim for glide.

- Mount the receiver to the bottom of the wing as far forward as the servo wires will allow using some of the included velcro.

- Tape the servo wires down to the wing to hold them in place using blenderm.

- Attach the battery to the bottom of the wing using velcro as far forward as the JST adapter wire will allow. I waited to velcro the battery till I balanced the model and placed the lead shot in place.

- Insert your heaviest loaded rocket motor into the motor mount

- Support the model upside down at the balance point indicated for boost. Glue pieces of the included lead shot against the dam as far forward as possible as needed to balance it. Do not try to fly the model too nose or tail heavy. Remember, a nose heavy model flies poorly, a tail heavy model flies once. I added a little at a time and glued it in place using foam safe CA and then checked the balance and repeated till it was good.

- I can only recommend testors/model master enamel spray at this time, others I’ve tried damage the foam surface. I recommend Model master flat black. Remove the battery and receiver and tape over the servo connectors so you won’t get paint in them before painting. You should mask over the rail buttons as well.

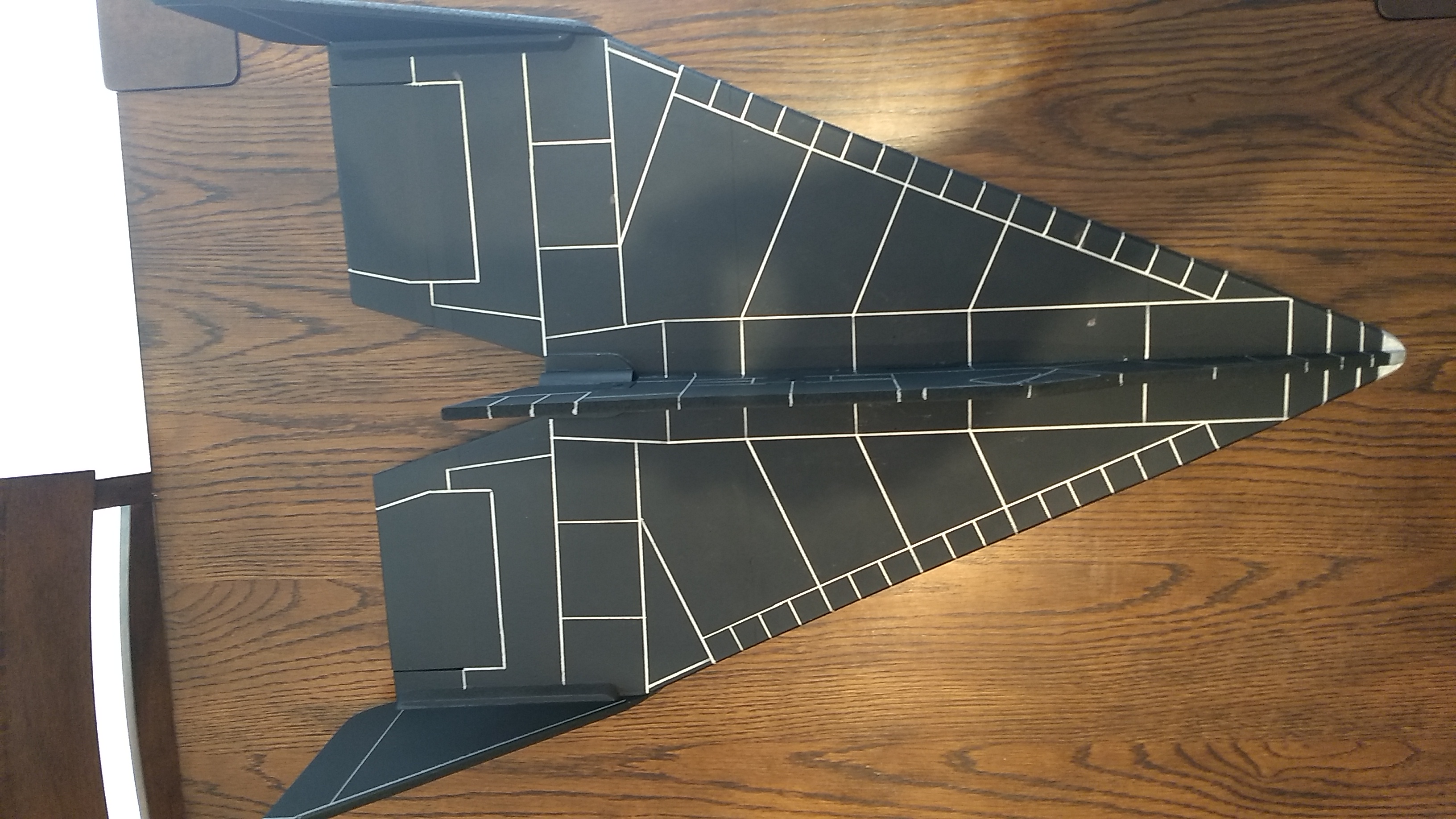

- You can use a silver fine line sharpie to add panel lines if desired.

- Re-install the receiver and battery, and re-check the balance point again to be sure the paint didn’t shift the CG after painting, add more nose weight if needed.

Flying: See the General Instruction link at the top for flying instructions. Be ready on the first few flights to keep the model straight till you have the trims set perfectly for boost and glide.

- Glue front tape joint

- Make sure Wing lays flat as joints set.

- Rail button location

- Glue a styrene plate onto each side of the fuse centered over the two pre-made holes

- Install a T-nut into each plate

- then install the rail button and screw into the other side.

- Rail button styrene disks and buttons added.

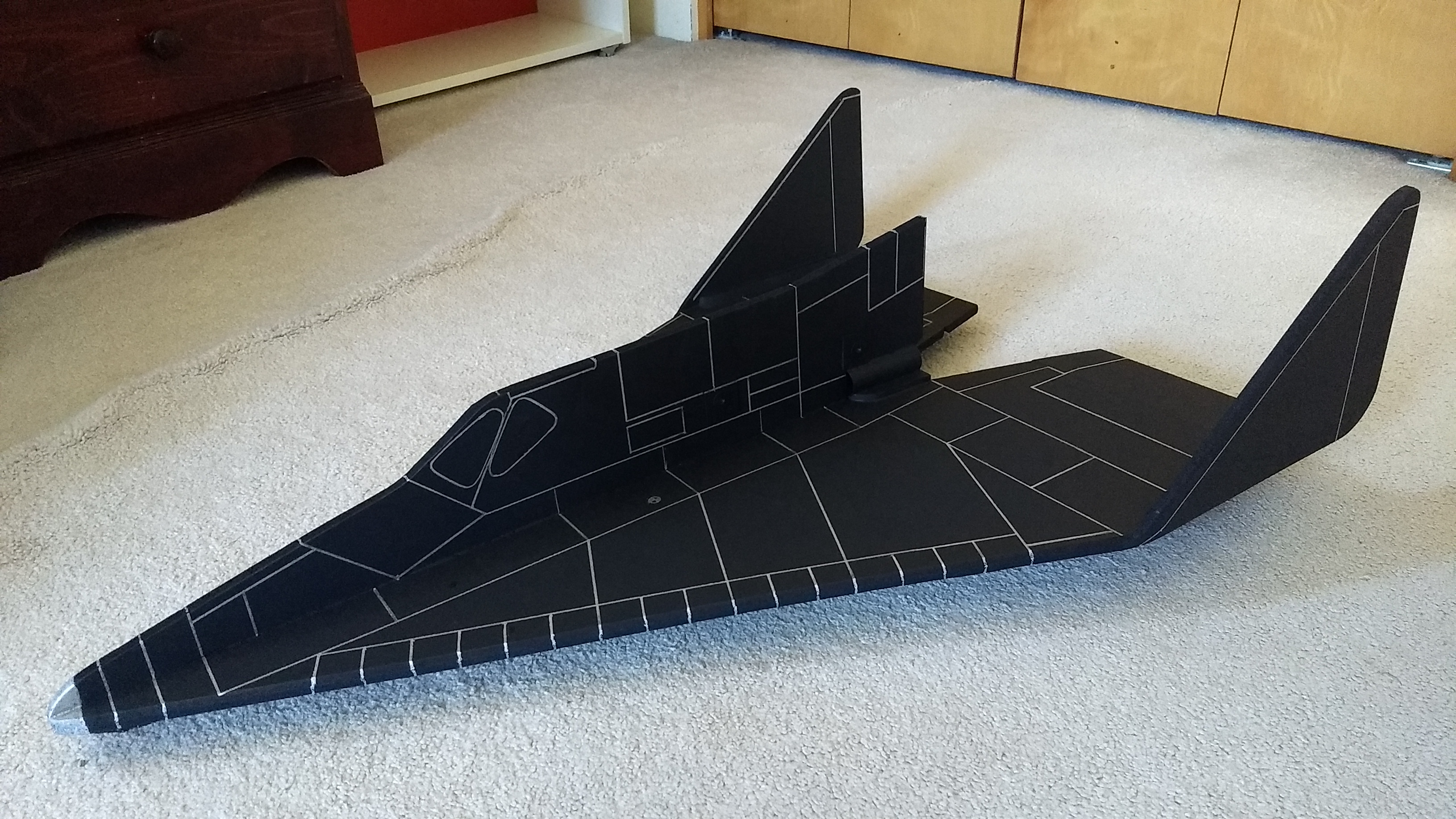

- Completed airframe.

- Nose weight added.

- completed model

- Top view

- X-20 3-view