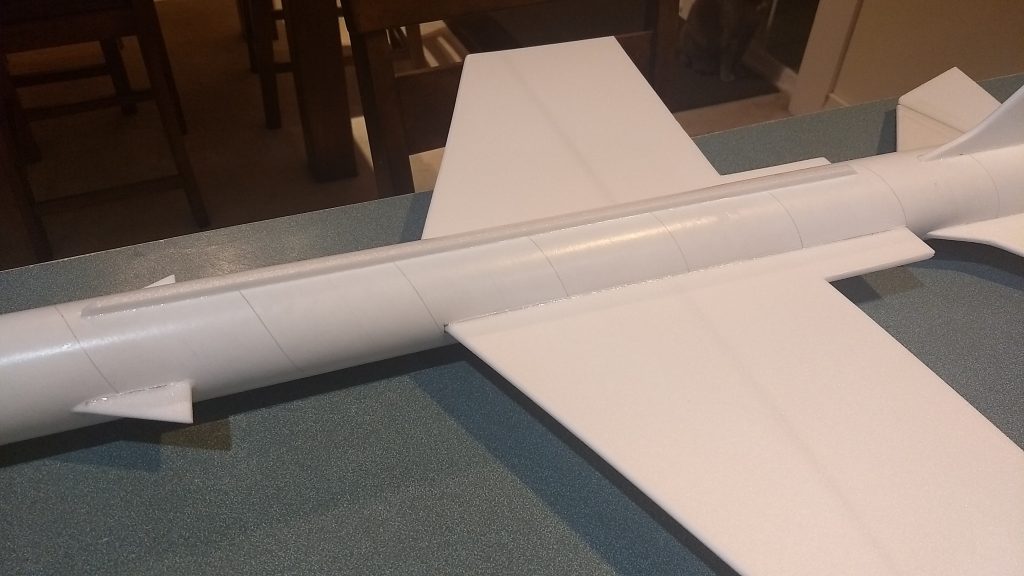

The Space Transporter America RC Rocket glider kit is modeled after the Estes futuristic Shuttle concept. It comes with a plastic nose cone, 2.6″ white tubing for the body and Depron wing and tail surfaces. You will need two 10 gram type servos, two 24″ servo extensions, a receiver, and a small 500mah single cell lipo battery. You will need a transmitter with delta or elevon mixing and a lightweight sub 10 gram receiver. Please refer to the general instructions link above, then read the instructions completely before starting assembly. The assembly photos are for general reference but may not include every step in the instructions. Stickershock23 can provide decals HERE, I added a bunch of other details on my prototype model by hand using a black fine and thick sharpie and some paint accents(silver)

CG location for rocket flight: 16 3/8″ forward from the rear of the body tube. 23″ wingspan, 40″ length, 2.6″ diameter, 11.5 oz rtf.

Welcome to the world of rocket boosted radio control gliders. This is not a model for a novice RC pilot, but anyone who is comfortable with flying a medium speed aileron equipped model should be fine. Read through the instructions, look at the photos and be sure you understand the step before comitting to cutting or glue.

Identify all pieces, the kit should contain:

1 wing with spars installed.

2 horizontal stabs with surfaces hinged and spar installed

1 Nose Cone

2 pushrods

2 Canards

1 Foam conduit strip

1 vertical stab

2 Body tubes

1 Coupler

Motor mount

3 foam centering strips for motor mount.

Velcro(for battery and rx/bec attachment)

2 Rail buttons with t nuts/screws

Battery adapter for 1s Lipo to rx

Lead weight

Spare foam

Notes before starting:

Reference to CA+ means foam safe CA+, normal CA+ will melt the foam! Normally you need to use accelerator to get the CA to set on the foam since there is nothing for it to soak into and activate.

You may use 220-320 grit sandpaper and a sanding block to slightly round or taper the edges of the foam if you prefer that look. It will not markedly impact the flight performance either way. Be very careful and use a light touch, it is very easy to catch the foam on the edge of the paper and tear the foam. Do any sanding before assembly.

Epoxy is not needed in this model. Weight is critical and the model is designed for the thrust and flight loads. Weight in the rear end is bad and will require additional weight in the front of the model.

Assembly:

- If not installed already, install the two rail buttons/t-nuts in the holes pre-cut in the body tube. Do this at this time.

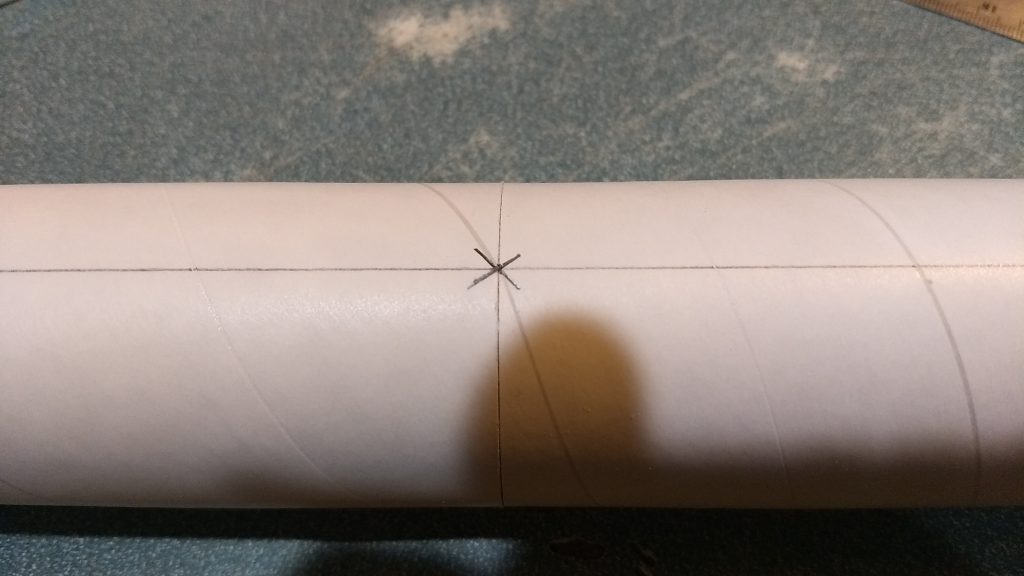

- Join the two body tubes using the provided coupler with the arrow mark aligned on the body tubes(to make sure the wing surfaces are aligned with the canards.

- If you are going to use a silver vinyl strip between the wing and tail surfaces, it’s better to make a template at this time. Take a piece of paper 12″ by 3″ wide, wrap it around the body tube so that the front is just on the top mark where the top conduit will end. Then, use a pencil to mark where the wing/vertical/horizontal stab slots are. Use this to mark and cut the silver decal, I’d apply it in 3 pieces once the assembly is complete.

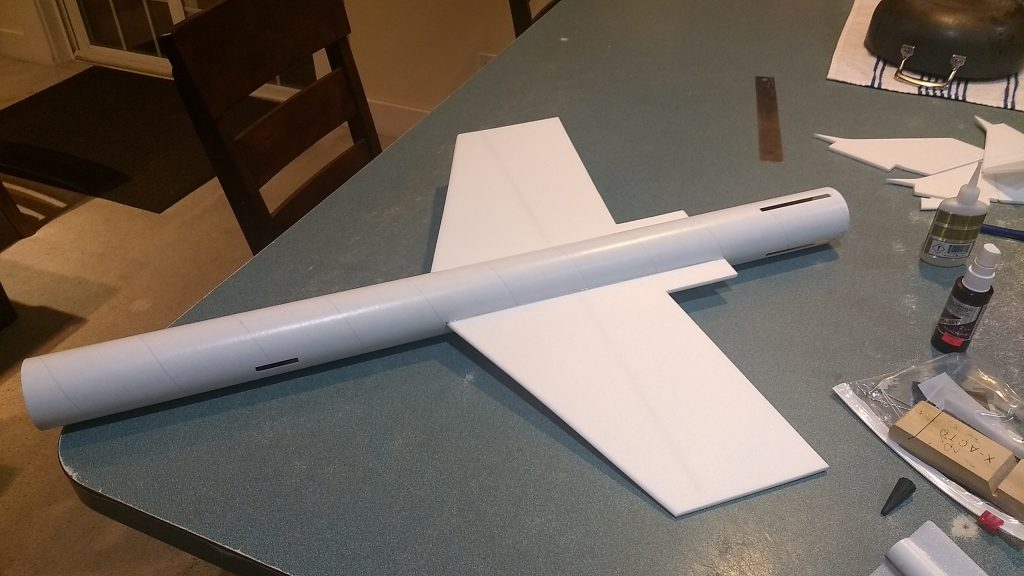

- Test fit the wing into the body tube slot, make sure it is centered then glue in place.

- Glue the vertical stab(the part without carbon spar or hinged surface) into the long slot at the rear, make sure it is perpendicular to the wing, put a fillet of CA on the outside and inside joints and set it with accellerator.

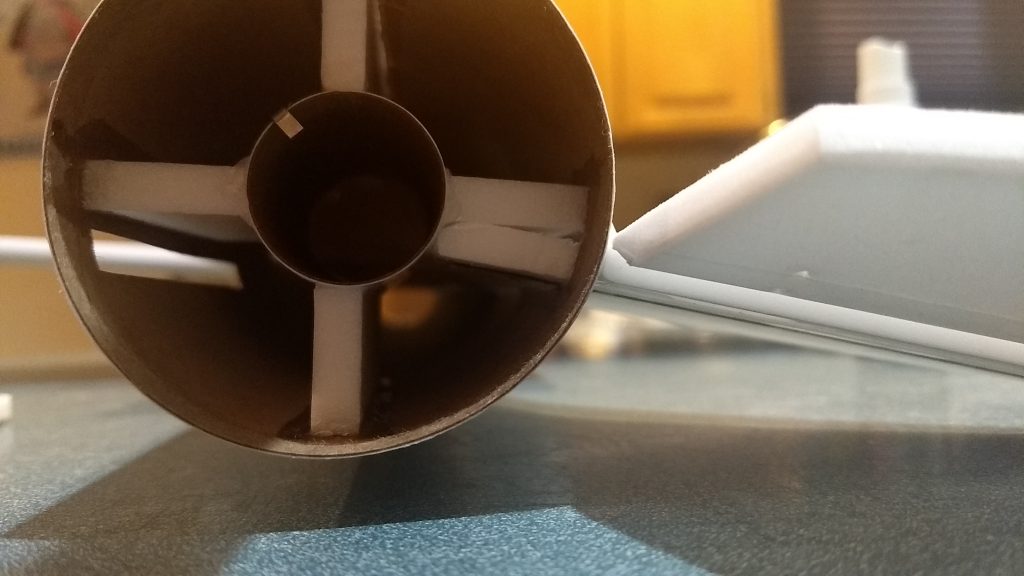

- Glue the three foam centering tabs onto the motor mount on the lines marked. If your kit came with a motor block glue this to the front of the motor tube at this time.

- Test fit the motor mount into the rear of the model. It should slide under and be a snug fit under the vertical stab tab. Sand the foam tabs on the motor tube slightly till it fits and insert it so it is recessed 1/2″ into the rear of body tube. Make sure the vertical stab stays perpendicular to the wing and the horizontal tabs on the motor tube are evenly spaced above the cutouts on each side of the body tube. The Horizontal stabs will butt against these tabs and they set the down angle on the stabs so you want them symmetric.

- Once the fit is correct, run a bead of CA+ down each joint inside the body tube and the vertical stab. Make sure not to get glue on the motor hook as it needs to move. You don’t need tons of glue here as it just needs to keep from moving forward under thrust.

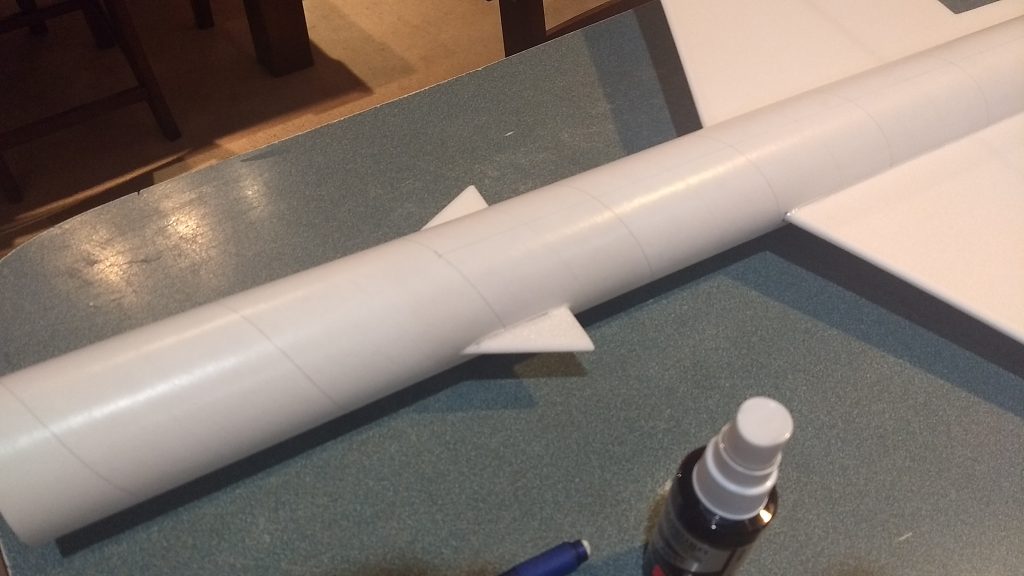

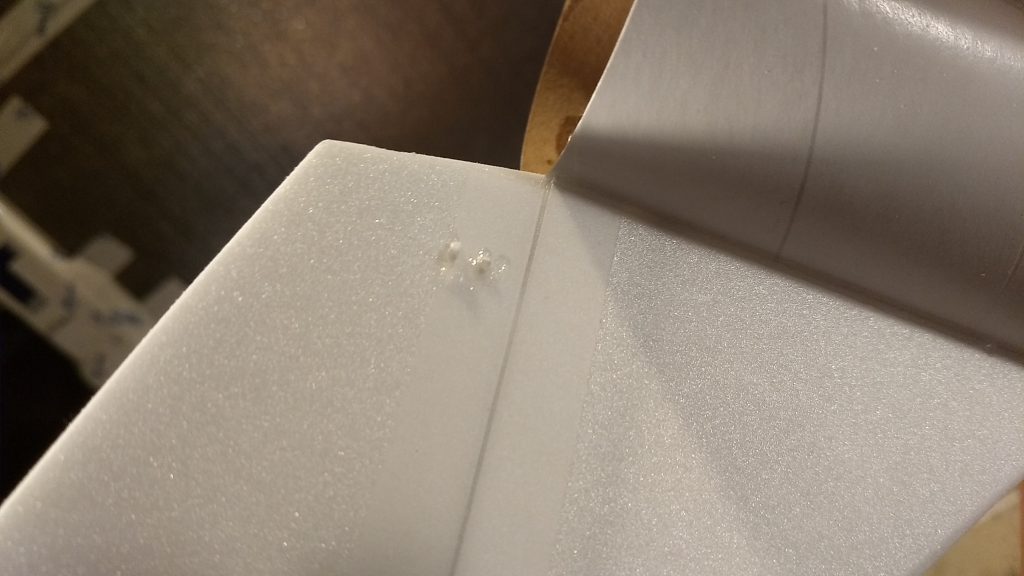

- Test fit each horizontal stab into the slots. The spar will face down on each side. Make sure each stab butts against the body tube at the front, lightly sand the root edge of the stabilizer till it fits flush and contacts the motor tube. The horizontal stab tab will but against the underside of the foam motor tube tab. If the angle of the left and right sides are slightly mismatched you can sand the top of the tab corner on the stab that is less angled, to allow it to angle down slightly more, you just want them approx equal. Remove a stab and apply glue to the root edge of one stab and insert it into the slot. Hold it in place till it is set, then apply a bead of CA on the outside and inside areas of the body tube and where the root hits the motor tube. Repeat for the other side, making sure the down angle is approximately the same as the other side.

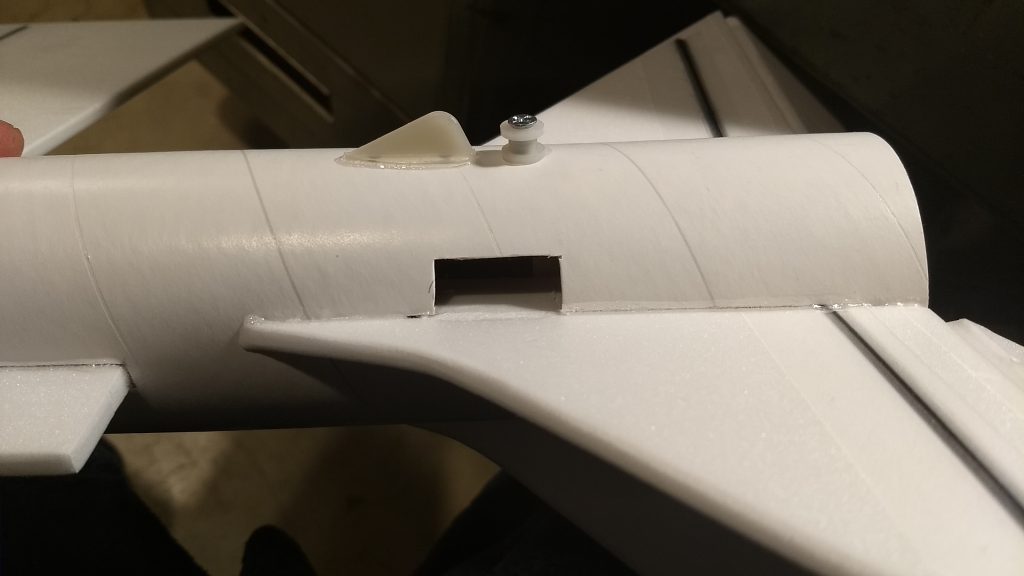

- Glue a pushrod/control horn into the bottom of each elevator half in the pre-made holes. The holes will face forward and I prefer to have the pushrod on the side closest to the body tube.

- Apply some foam safe CA+ to the top of the prongs to lock them in place.Glue the two canards in place in the forward slots, make sure they are aligned with the wing.

- Glue the top conduit strip in place on the line marked.

The basic construction is now complete.

Radio Installation

Note: Your radio needs to be configured for Delta mixing, this means that the servo arms will move the same direction during elevator stick movement and opposite for aileron stick movement. Connect your servos to the receiver one in the aileron connection and one on the elevator connection and apply power. Use a servo arm at least 9/16” long Zero out any trim settings on the transmitter.

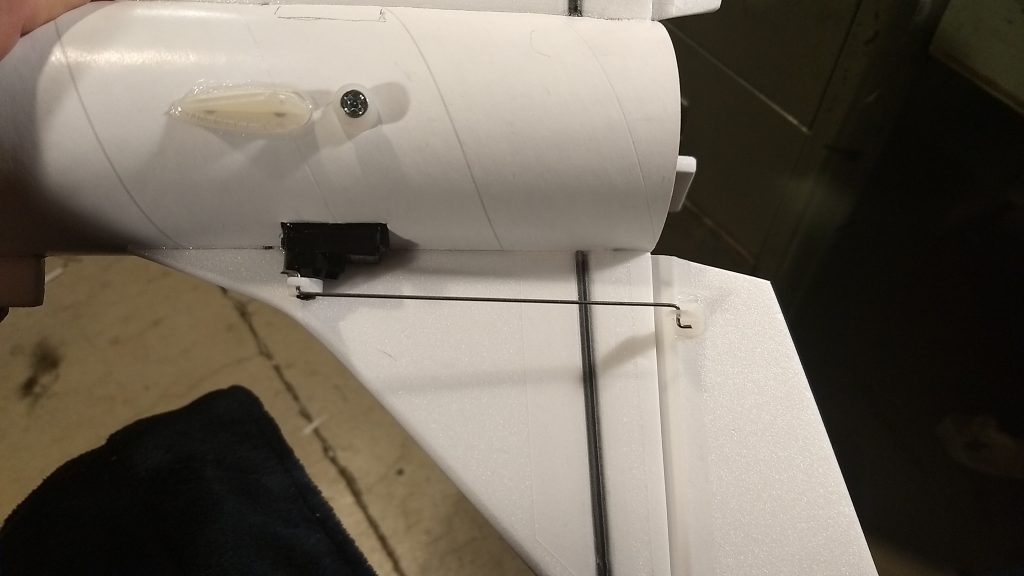

- Insert each pushrod into a servo arm. Note where the servos will sit on the bottom of each horizontal stab when the control surface is neutral. Cut a pocket into the body tube to fit the servo. The pushrod will be pointing up when the model is placed upside down on a flat surface.

- Attach a 24″ servo extension to each servo.You just need to be able to route the wire to the front of the tube to attach it to the receiver. Route them into the servo pocket in the body tube toward the front and install the servos. Install the servos so that the electrical wire points forward.

- Tape the servos in place temporarily and flip the model right side up.

- Moving the transmitter stick back(up elevator) should move both stabilizers trailing edges up. Moving the transmitter stick to the right should move the right elevator up and the left down. If you can’t get the servo reversing to give you the right polarity try swapping aileron/elevator inputs to the receiver If that is correct, continue.

- Make sure the control surfaces are centered, and glue the servos in place to the foam so that the control surface is flat.

- Make sure the control surfaces are level and the servo glue has set.

- Now measure the control surface movement. Full elevator movement should be 1” in each direction, roll/elevon movement should be 5/8″ to 3/4″ in either direction. Since the model will be nose heavy, extra elevator movement helps to give sufficient authority during glide.

- If you have a flap/elevator mix you can program up elevator to a switch setting. The model needs approximately 1/4″ of up elevator trim during glide. If you can’t set the up elevator trim to a switch on your radio you’ll have to manually put in boost and glide trim which is hard to do while flying the model.

- Use the included Velcro to attach the battery and receiver in the nose cone.

- Insert your heaviest loaded rocket motor into the motor mount

- Support the model at the balance point indicated for boost. I use two pencils with the eraser pointed up and held in place with a small hand vice. Place the model on the pencil erasers on the balance point indicated above. Use the included lead weight to balance it. Do not try to fly the model with it balancing it behind this point. The adage is, a nose heavy model flies poorly, a tail heavy model flies once

- You may paint the model with model master or testors small rattle can enamel paint. Use the scrap piece of foam to test your paint to make sure it won’t melt the foam.

- If you use the stickershock decals, it helps once applied to use a hair dryer on hot to soften the material and then push it down onto the model with a towel. It helps it conform and stick much better.

- Use a black/silver sharpie to add panel lines and accents if desired.

Flying: See the General Instruction/Information link at the top for flying instructions. Be ready on the first few flights to keep the model straight till you have the trims set perfectly for boost and glide.

- Join the two tubes so that the line mark is aligned

- Install wing and glue in place when centered

- Glue in the vertical tail

- Install the 3 motor centering tabs on the motor tube, note the position of the motor hook

- Install the motor mount inset about 1/2″

- test fit then glue one of the horizontal stabs in place

- Note how the stab tab abuts the motor tube and touches the foam motor centering tab to set the angle.

- Both stabs installed.

- Install the two canards in the slots keeping them parallel with the wings.

- Install the foam conduit on the line marked

- Install pushrod and glue in place, attach servo to pushrod and mark where servo pockets will need to be cut.

- Apply glue to the top of the control horn prongs to lock them in place

- Cut pocket for servos

- Test fit servo into pocket, then attach to pushrod and glue in place so that control surface is level.

- Receiver and battery installed into the nose cone with included velcro.

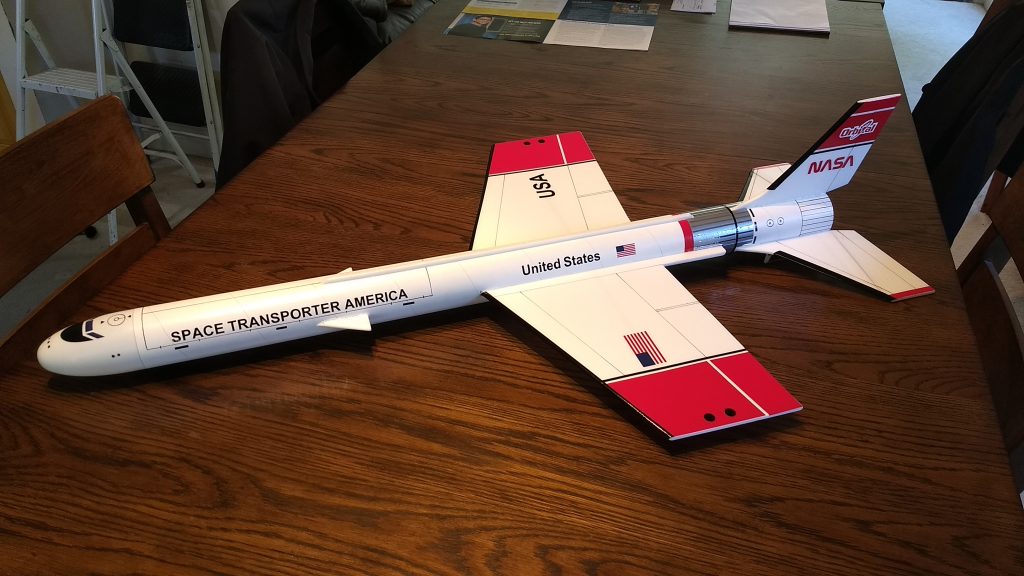

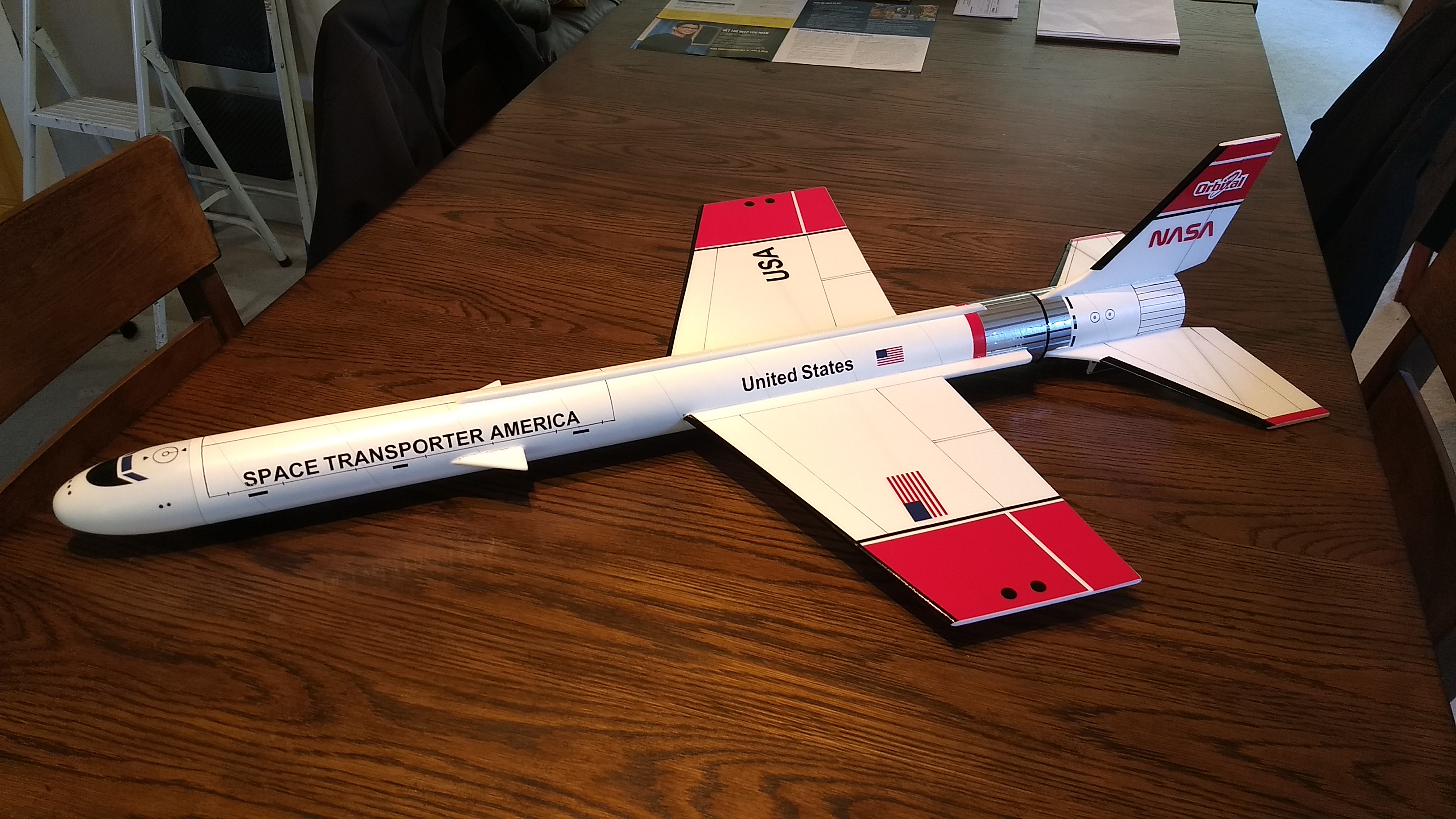

- Airframe complete

- Original Estes model for reference on marking locations and panel lines/details

- Completed model Ready to fly

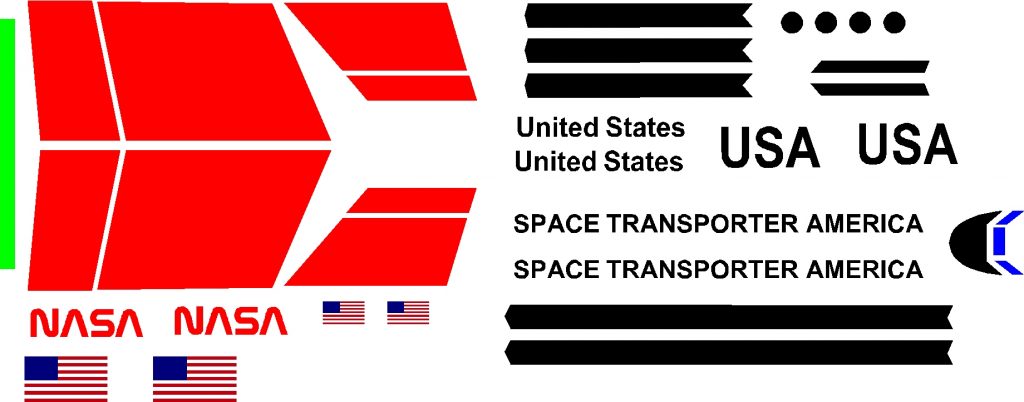

- Example of stickershock markings