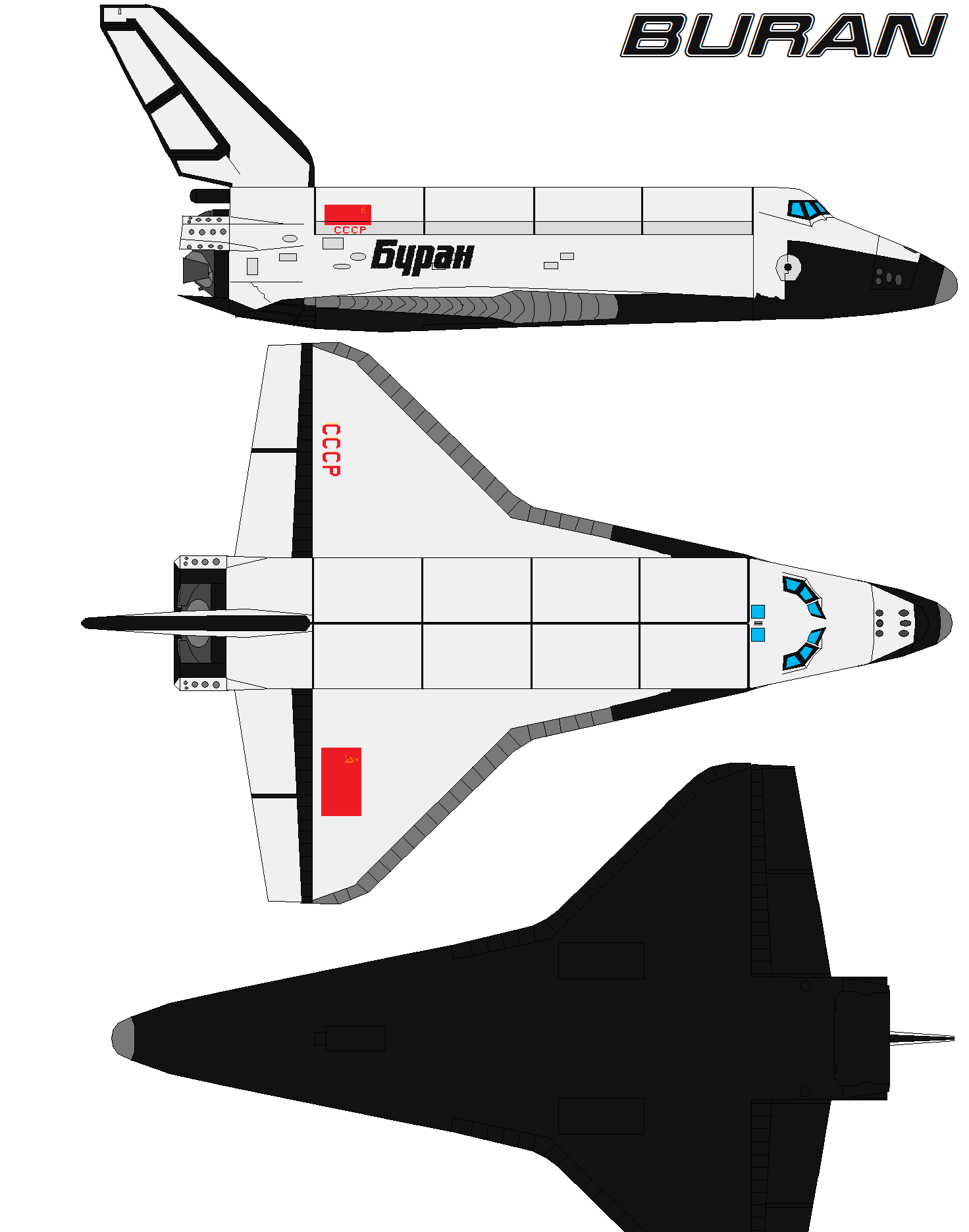

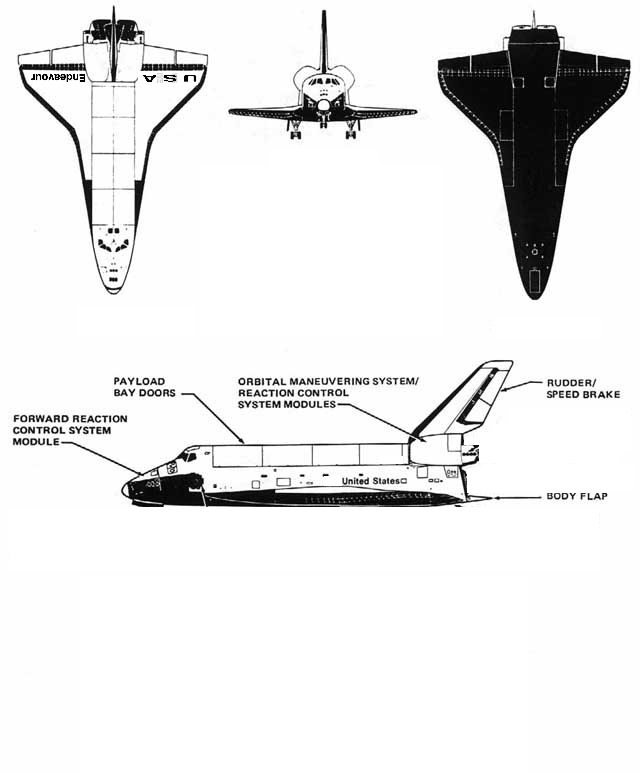

The Shuttle RC Rocket glider kit is based on both the secretive Soviet era Buran and US Shuttle designs. The Buran was flown to orbit with an autonomous unmanned return to earth. The US Shuttle was a workhorse of Nasa for many years. The model is approximately 1/72 semi-scale. It comes with white tubing for the body, and 6mm depron wing and tail and cockpit surfaces and 3mm side plates. The body tube is pre-slotted for the tail and rail button holes are pre-punched. Elevons are pre-hinged and the spar is pre-installed. Length 21″, wingspan 18″, diameter 2.6″, weight 8.5 oz (140 grams) ready to fly. The model is designed to use composite 24mm E-6 rocket motors only. Please refer to the General information for all kits tab above, then read these instructions completely before starting assembly. You will need short 3-6″ servo extensions to attach the servos to the receiver at the front of the model. Excellent high quality cut vinyl decals for both Buran and US shuttle are available separately HERE:

The Shuttle RC Rocket glider kit is based on both the secretive Soviet era Buran and US Shuttle designs. The Buran was flown to orbit with an autonomous unmanned return to earth. The US Shuttle was a workhorse of Nasa for many years. The model is approximately 1/72 semi-scale. It comes with white tubing for the body, and 6mm depron wing and tail and cockpit surfaces and 3mm side plates. The body tube is pre-slotted for the tail and rail button holes are pre-punched. Elevons are pre-hinged and the spar is pre-installed. Length 21″, wingspan 18″, diameter 2.6″, weight 8.5 oz (140 grams) ready to fly. The model is designed to use composite 24mm E-6 rocket motors only. Please refer to the General information for all kits tab above, then read these instructions completely before starting assembly. You will need short 3-6″ servo extensions to attach the servos to the receiver at the front of the model. Excellent high quality cut vinyl decals for both Buran and US shuttle are available separately HERE:

CG location for rocket flight: 8″ forward of the rear end of the wing where it hits the body tube.

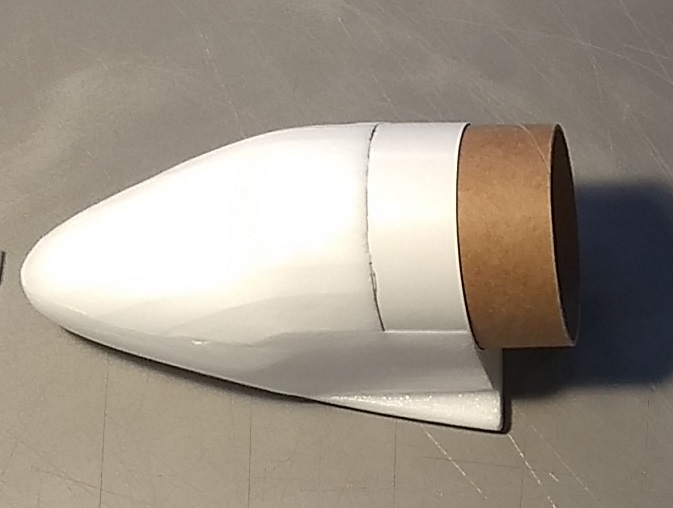

Boyce Aerospace is offering a 3-d printed nose cone that fits the Buran/US Shuttle and a plug in display nozzle set for the US Shuttle that will fit this model HERE The nose cone requires a small trimming of the front of the wing to line up with the shorter cone assembly which is covered in the instructions below. CG and overall weight of the model is identical.

Welcome to the world of rocket boosted radio control gliders. This is not a model for a novice RC pilot, but anyone who is comfortable with RC flying of a medium speed model should be fine. Read through the instructions, look at the photos and be sure you understand the step before commiting to cutting or glue.

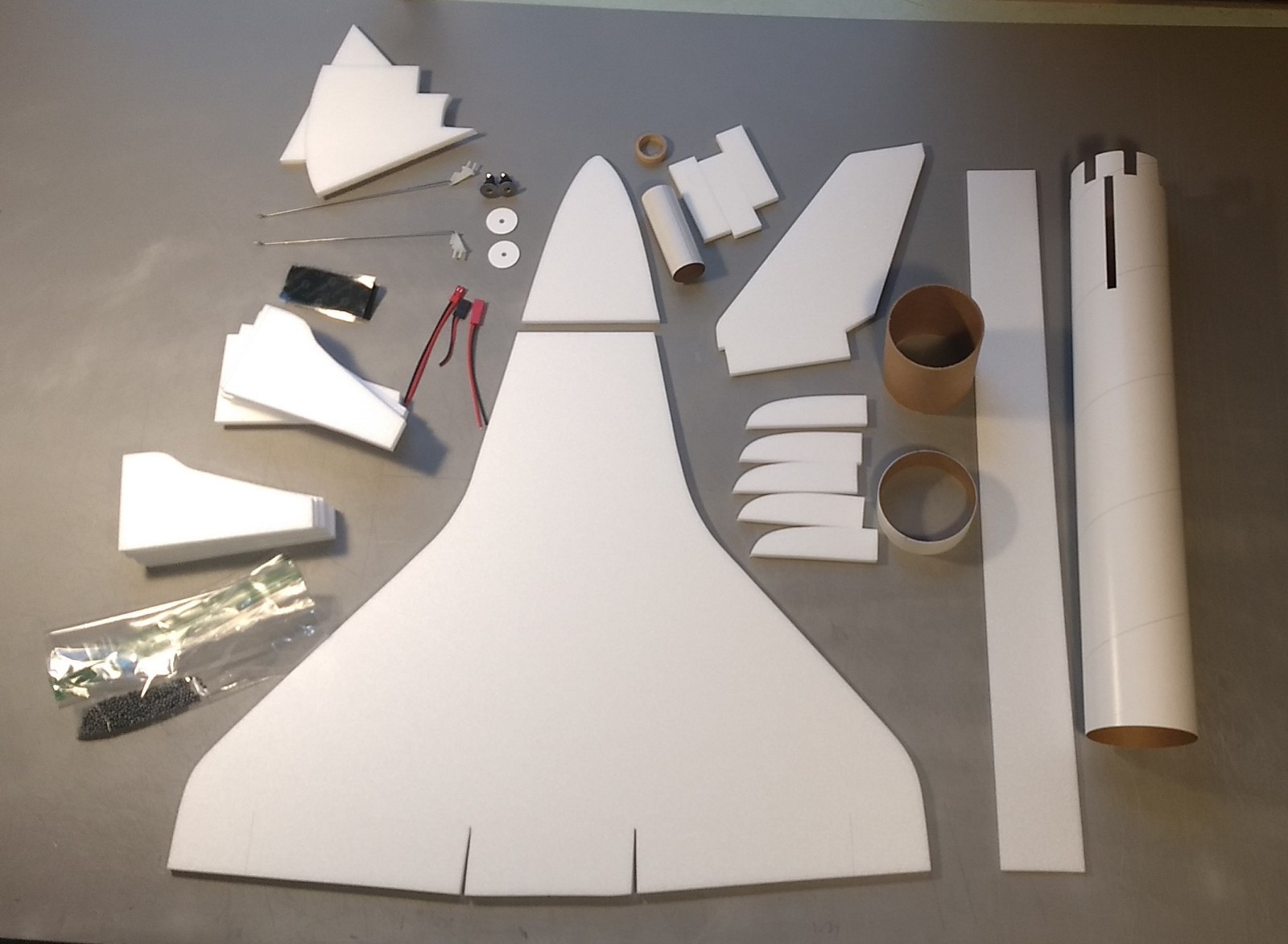

Identify all pieces, the kit should contain:

1 wing taped together 6mm depron

1 wing nose section 6mm depron

11 Nose section profiles 6mm depron

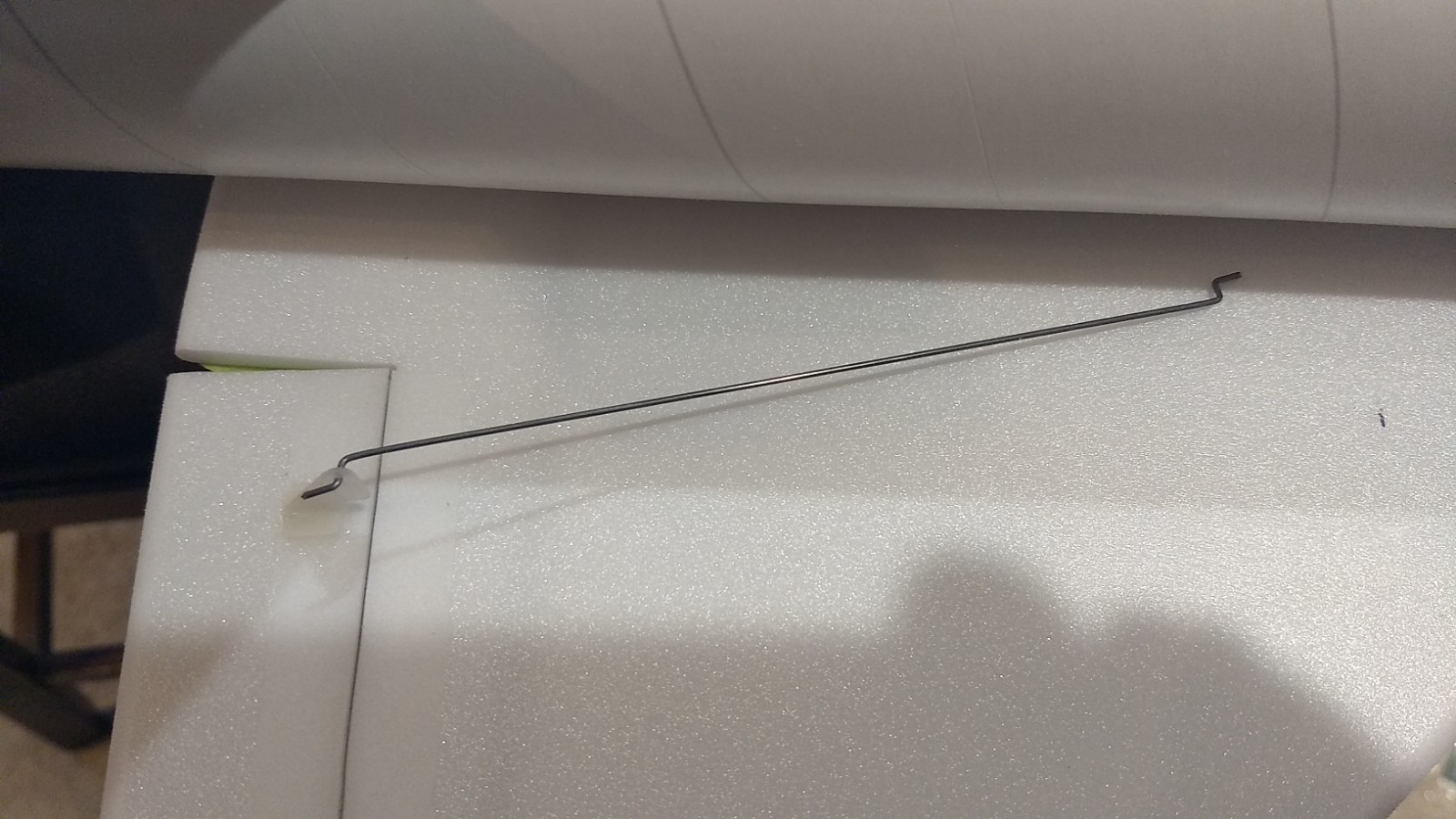

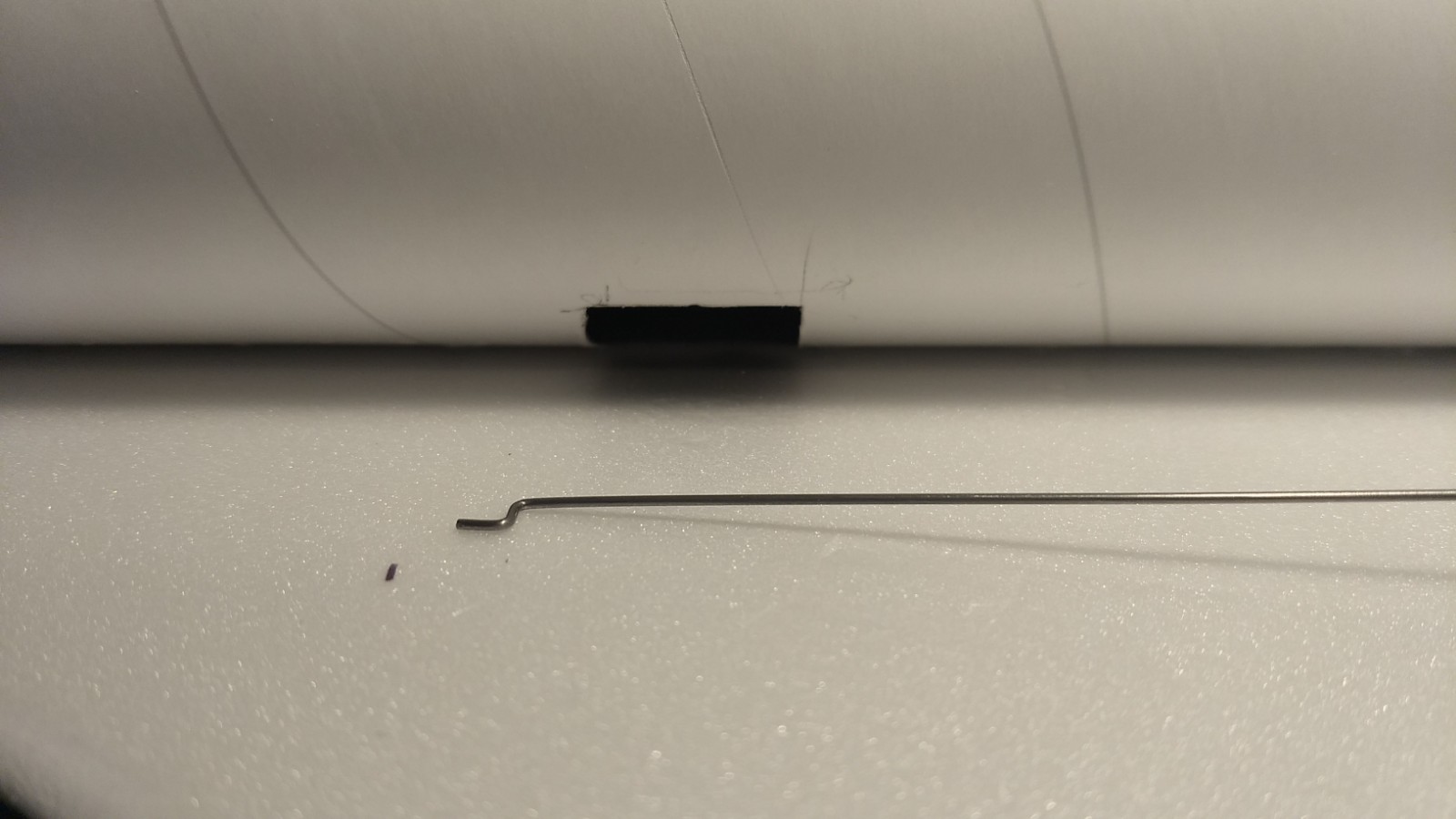

2 pushrods 2/horns

1 vertical stabilizer 6mm depron

1 16″ Estes/BMS lightweight BT-80 Body Tube

1 1″ long Estes/BMS lightweight BT-80 body tube

1 2″ long BT-80 coupler

24mm Motor mount

3 13/16″ x 2.75″ 6mm depron strips to center the motor tube.

Velcro(for battery and rx/bec attachment)

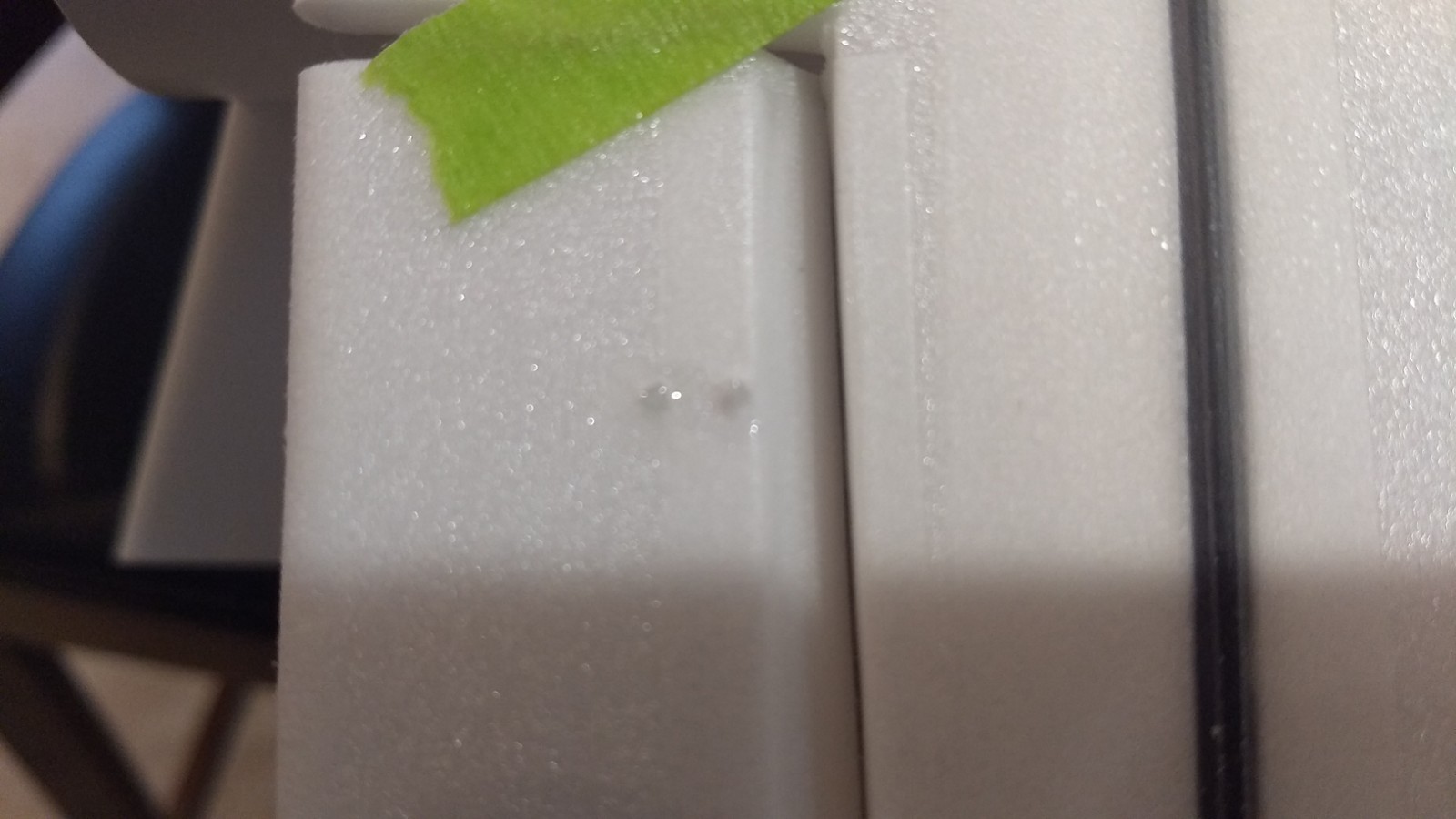

2 Rail buttons with t nuts/screws(some kits may include both short and long screws)

2 .03 styrene rail button supports

2 3mm depron long side plates

2 3mm depron short side plates

12 OMS Pod plates(optional)

Thrust ring

Lead weight

Spare foam (for testing paint, glue, and sanding the edges to see how it behaves)

Notes before starting:

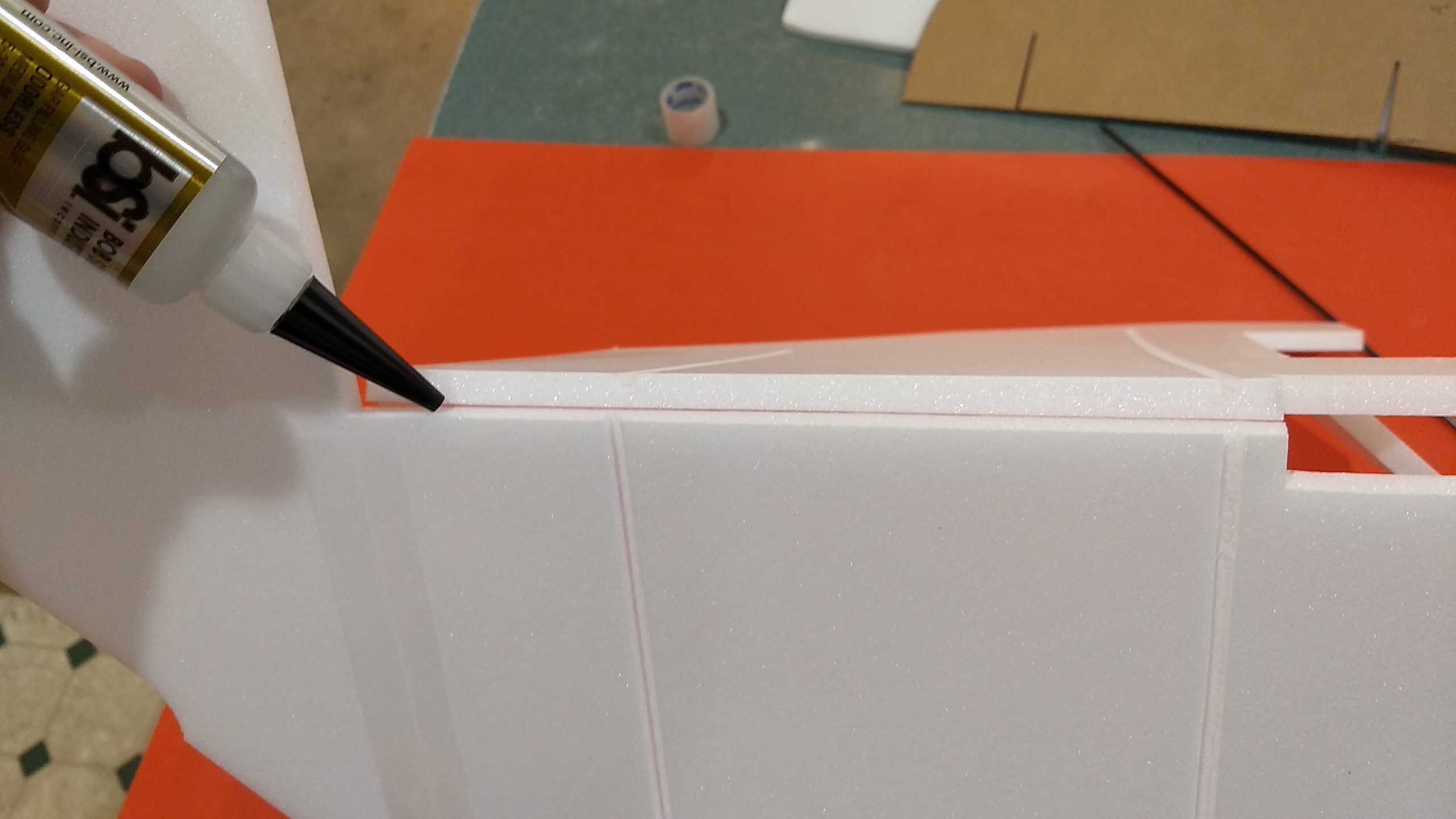

Foam safe CA+(Bob smith super gold + is good) is the only glue recommended for construction. You will also need foam safe accellerator to set the glue.

You may use 320 grit sandpaper and a sanding block to slightly round the edges of the rear foam wing and vertical stab if you prefer before gluing the wing and vertical stab in place. You can also taper/round the top of each side plate. use a light touch to avoid tearing the edges of the foam. The nose/cockpit and forward wing will be shaped after assembly.

Assembly:

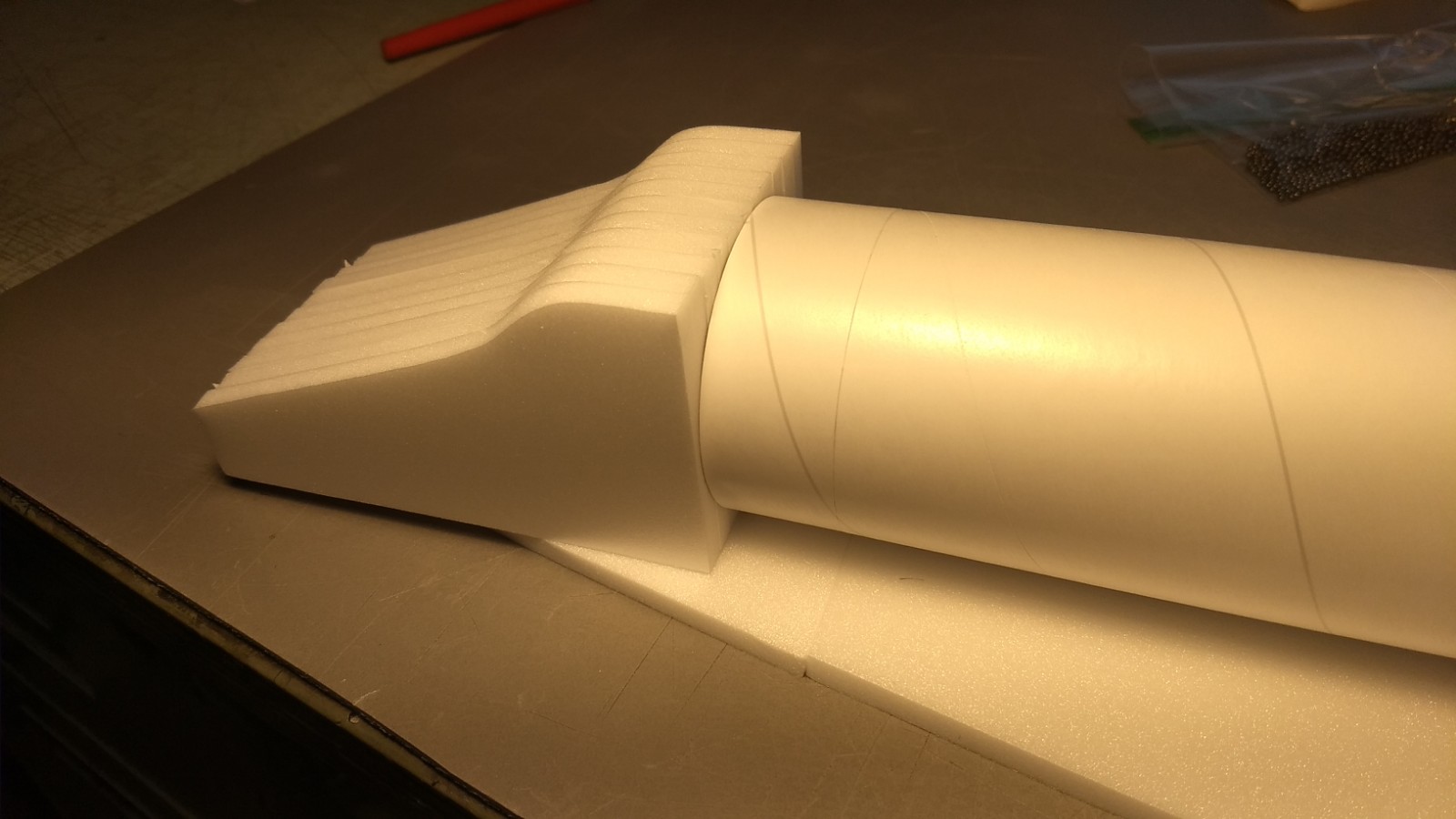

- The wing is made of three pieces, a forward pointed part, and the rear wing with a short piece taped in place with blenderm tape to allow the wing to fit into the shipping box. If the front pointed part of the wing is taped temporarily in place with masking tape, remove it and set it aside. Do not remove the clear blenderm taped part!!

- Glue the blenderm taped wing joint and lay flat to set.

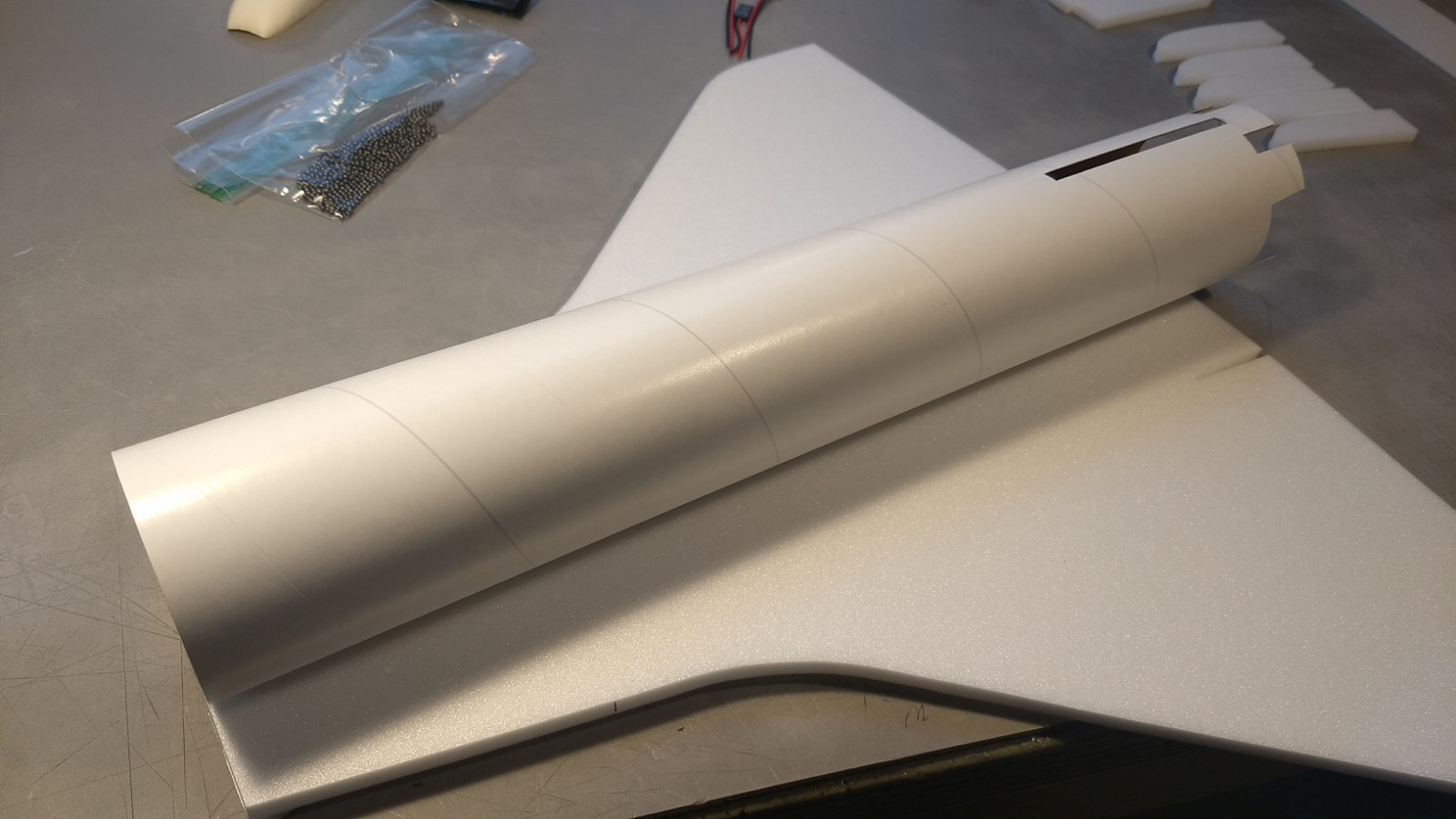

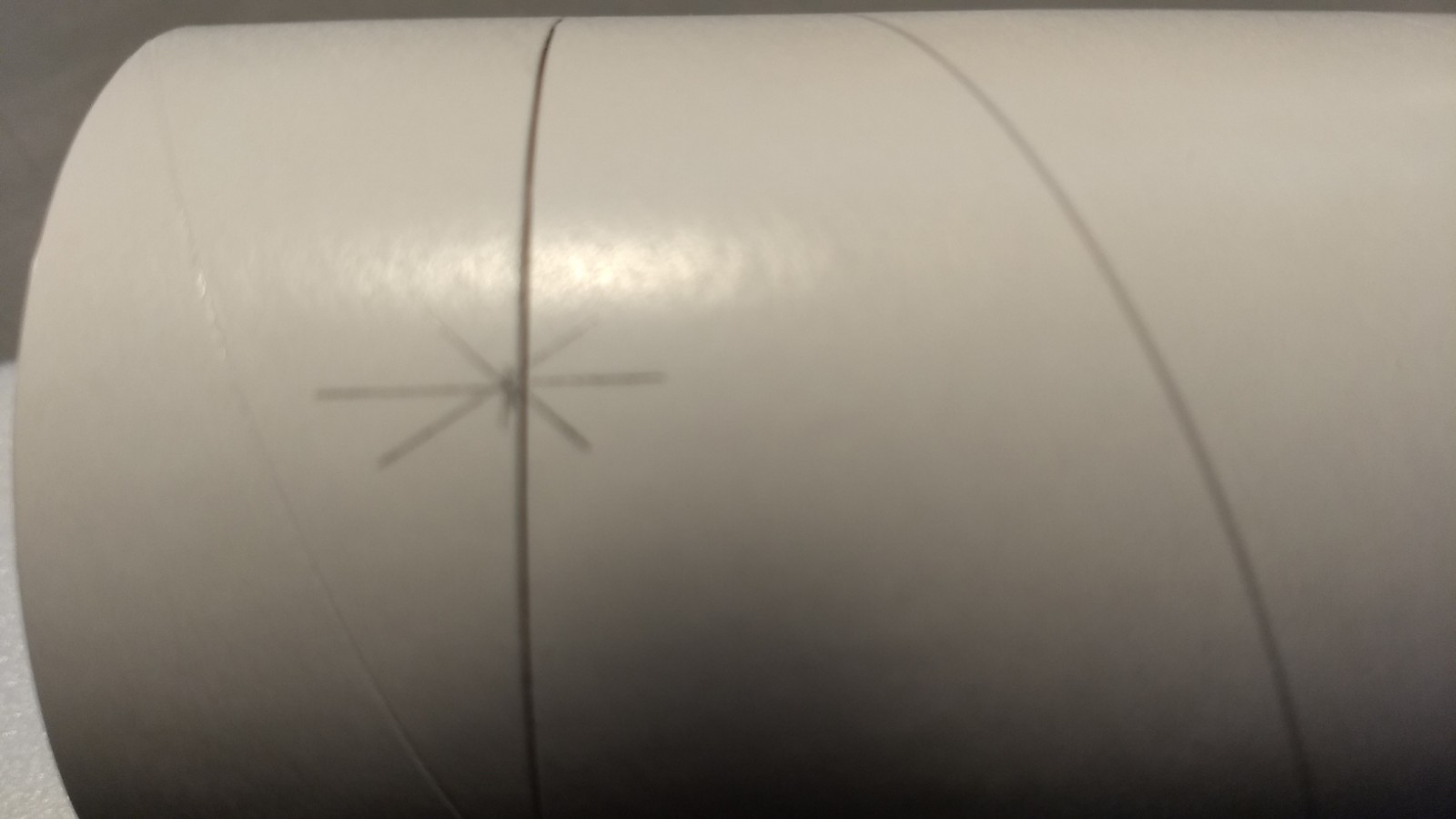

- Apply glue to the wing line on the bottom of the body tube, lay the body tube on the top of the wing and make sure the front and rear alignment lines are lined up with the center of the wing at the front and back. **Note the front of the wing will be even with the front of the body tube. DO NOT GET GLUE close to the pre-punched rail button holes as these will need to be clear for mounting the rail buttons later!!

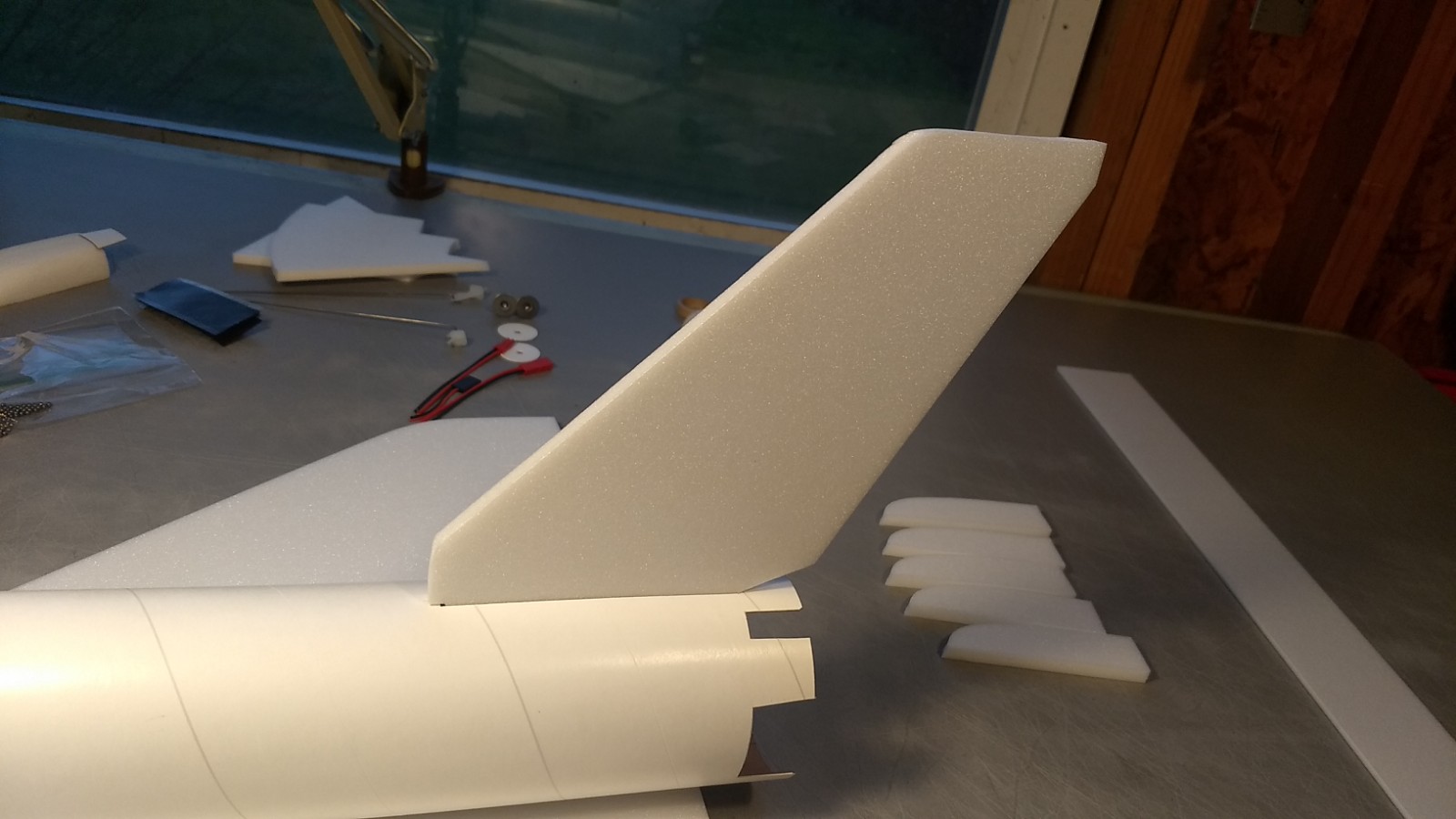

- Test fit the vertical stab into the slot in the body tube carefully. Glue the vertical fin into place keeping the fin perpendicular to the work surface. Apply a light filet to both sides of the vertical stab on the inside and outside of the body tube.

- Tape the front wing piece that is separate to the rear wing assembly with a small amount of tape on the bottom of the joint.

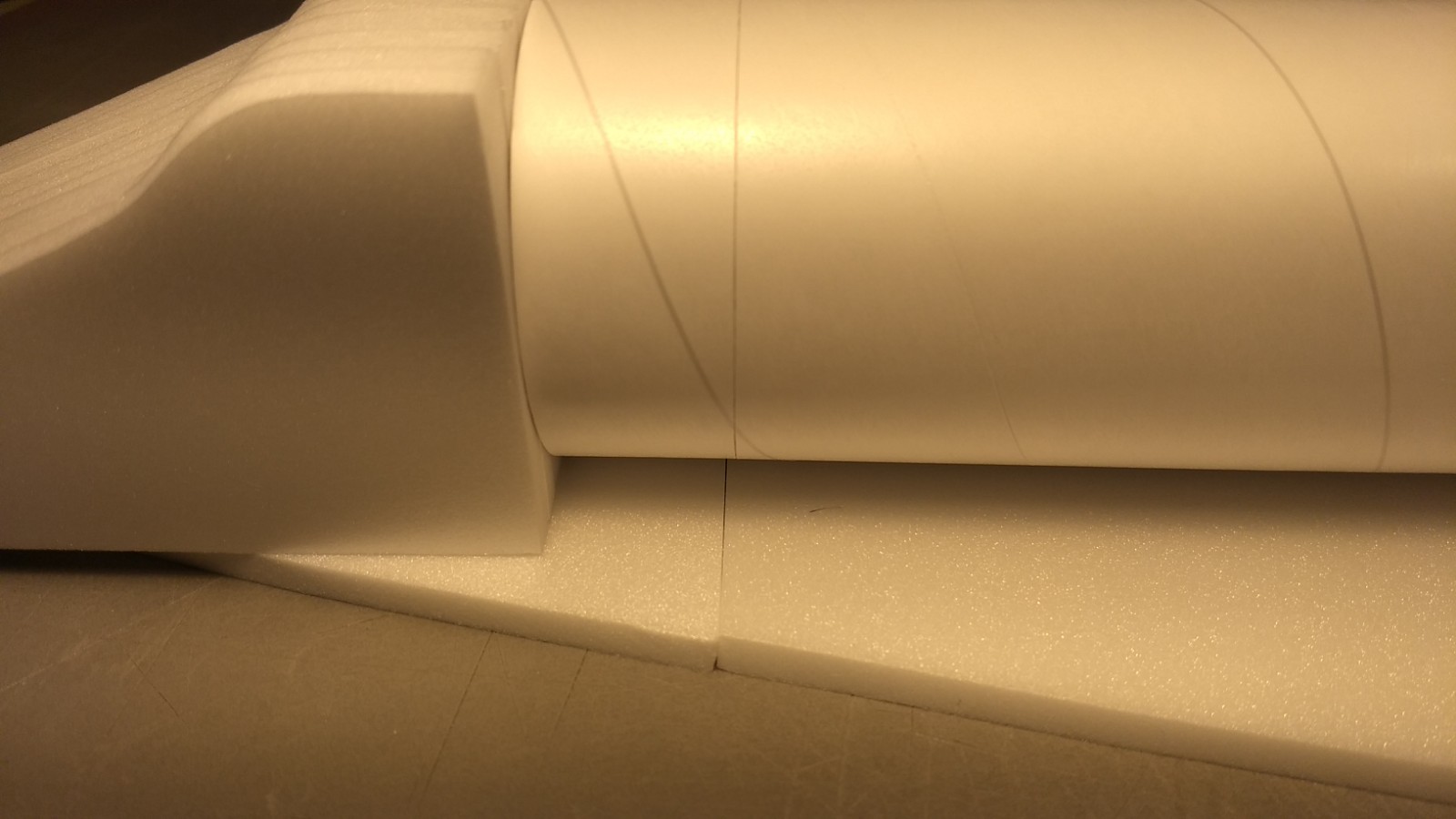

- Glue the 1″ body tube ring to one end of the coupler tube and make sure it is set. The pre-marked arrow should face the rear of the coupler so it can align with the rear body tube. The tubes are hand cut as good as I can cut them, but the arrow mark ensures they are aligned the way they are cut so that they mate perfectly.

- Insert the coupler assembly into the front of the body tube till it is fully seated and aligned with the arrow mark on the tubes.

- Carefully tack glue the 1″ body tube ring at the bottom where it contacts the forward wing piece, making sure not to get any glue into the taped joint, this piece will become part of the nose cone assembly and must be removable!

- Glue/laminate the 11 nose profile pieces together, I recommend 3m-77 contact cement sprayed on both surfaces, let dry for 1 minute then press together. UHU POR is also good, works the same way but you apply with your finger. You can use a thin layer of foam safe CA but that will leave hard ridges as you sand the nose to shape and will require more care. If you get any 3m-77 spray on areas you don’t want you can soften it with accellerator and wipe with a soft paper towel. Don’t spray too close to the foam or too heavy as the aerosol can melt the foam. Repeat for all of the pieces.

- Once set, sand the bottom and rear of the stack lightly to even them out.

- Glue the nose assembly to the forward bottom wing piece and to the body tube/coupler assembly, make sure the nose section is centered and there is equal material on either side of the body tube. The 3mm side plates will mate up to this overhang when installed.

- Remove the temporary masking tape on the forward wing and remove the cockpit assembly.

- Round/taper the top edge of each of the short 3mm side plates so they will blend into the body tube at the top and trim them to fit against the forward cockpit and the rear edge should be even with the rear of the short body tube piece. Glue in place against the body tube and cockpit and lower forward wing piece.

- Apply CA+ to each of the control horns and press them in place in the top of each control surface into the pre-made holes. Note the pushrods will angle inward toward the body tube, there is a left and right.

- Apply glue to the prongs on the bottom of the wing to lock the horns in place.

- Your radio needs to be configured for Delta mixing, this means that the servo arms will move the same direction during elevator stick movement and opposite for aileron stick movement. Connect your servos to the receiver one in the aileron connection and one on the elevator connection and apply power. Use a servo arm at least 9/16” long and with holes small enough that there won’t be slop with the pushrod wire when installed. I use the hole furthest out on the servo arm, to maximize movement. On some servos there are a long two-ended servo arm, you can trim off one end if needed to get sufficient length. Zero out any trim settings on the transmitter. The model once the motor has burned out is nose heavy and flying wings lose pitch authority when nose heavy so you want as much up elevator travel for trim/flare as possible.

- Connect a servo to each pushrod. If the pushrod is too tight, you can use twist an X-Acto knife in the servo arm hole to make it larger, but be careful and do not make it too large. Once connected, tape each servo in place so that the control surfaces are centered. Look at the model from the rear. Moving the transmitter stick back(up elevator) should move both elevons up. Moving the transmitter stick to the right should move the right elevon up and the left elevon down. If you can’t get the servo reversing to give you the right polarity try swapping aileron/elevator inputs to the receiver or turning the servos over and swapping the servo arms to the other side of the output shaft. If that is correct, continue.

- Disconnect the servos from the receiver.

- The servos may be attached to the model using double back servo mounting tape(not included) or by directly gluing the servo to the wing with foam safe CA+. Double back servo tape can loosen over time and with exposure to heat, I prefer to glue the servo in place.

- Mark where the servo will be when the control surface is neutral and cut a pocket into the body tube so that the servo is inset slightly. Repeat on the other side. Make sure your servo wire will be able to reach the front of the model to re-attach to the receiver in later steps. Depending on your servo you may need a short 3″ to 6″ servo extension installed at this time. Use lightweight ones if possible.

- Route the servo wire into the pocket on each side and toward the front. If you need to adjust the pushrod by bending the angle at the control arm so the servo is not angled, simply do so with a needle nose pliers before gluing the servo in place.

- Re-connect each servo to the reciever at the front of the model.

- Put a moderate amount of glue on the servo bottom, being careful not to get any near the output shaft, and set it in place on the wing in the pocket you just cut, keeping the control surface centered. Do the same to the other side. Make sure the glue is set before continuing.

- I sanded the top edge of each long side plate to a rounded taper to blend into the body tube when they are attached.

- Test fit the two side plates. You will need to cut a notch in each one to clear the servo and pushrod arm for free movement. The size of the notch will depend on your servos and how far in you recessed them. The side plates will be even with the front of the body tube and may hang past the rear of the wing slightly. Glue to the body tube as well as the wing.

- Connect the battery and power up the radio for this next step.

- Make sure the control surfaces are centered, use trims if needed. Now measure the control surface movement. Full elevator movement should be 5/8” in each direction, aileron movement should be 3/16″ to 1/4″ in each direction. Since the model will be nose heavy, extra elevon movement helps to give sufficient authority during glide.

- If you have a flap/elevator mix you can program up elevator to a switch setting. The model needs approximately 1/4″ to 3/8″ of up trim for glide. If you can’t set the up elevator trim to a switch on your radio you’ll have to manually put in boost and glide trim which is hard to do while flying the model. You can also use flight modes to set different launch and glide elevator trim settings and control those via a switch.

- Use the included velcro to secure the battery on the inside of the bottom of the nose cone coupler and use the remaining velcro to secure the receiver on the inside top of the body tube about 1″ back from the front so it clears the nose cone shoulder when installed. If your servo leads are long enough you can mount the receiver on the top inside of the nose cone shoulder but they have to be long enough to allow you to pull the nose off to access the battery.

- At this time you will carve/sand/shape the nose cone and blend it to match the top of the body tube and the side plates. Take your time. I started with 220 and then 320 and 400 grit paper, go slow and use a light touch. Tape over the exposed body tube to protect it from sanding. I used the outline of the front of the nose on the bottom to shape the blocks from the top view, then shape the side profile to round from the bottom of the front of the wing to curve the nose into a nice rounded shape, then rounded/shaped and contoured to match the body tube and side plates etc. Once done I lightly coated the cone section with foam safe CA, use a little at a time or it can melt the foam. This will harden the surface and make it more robust. You can also use a water based filler and sand if you are going to paint the nose section. I left my nose bare foam except for the black bottom area.

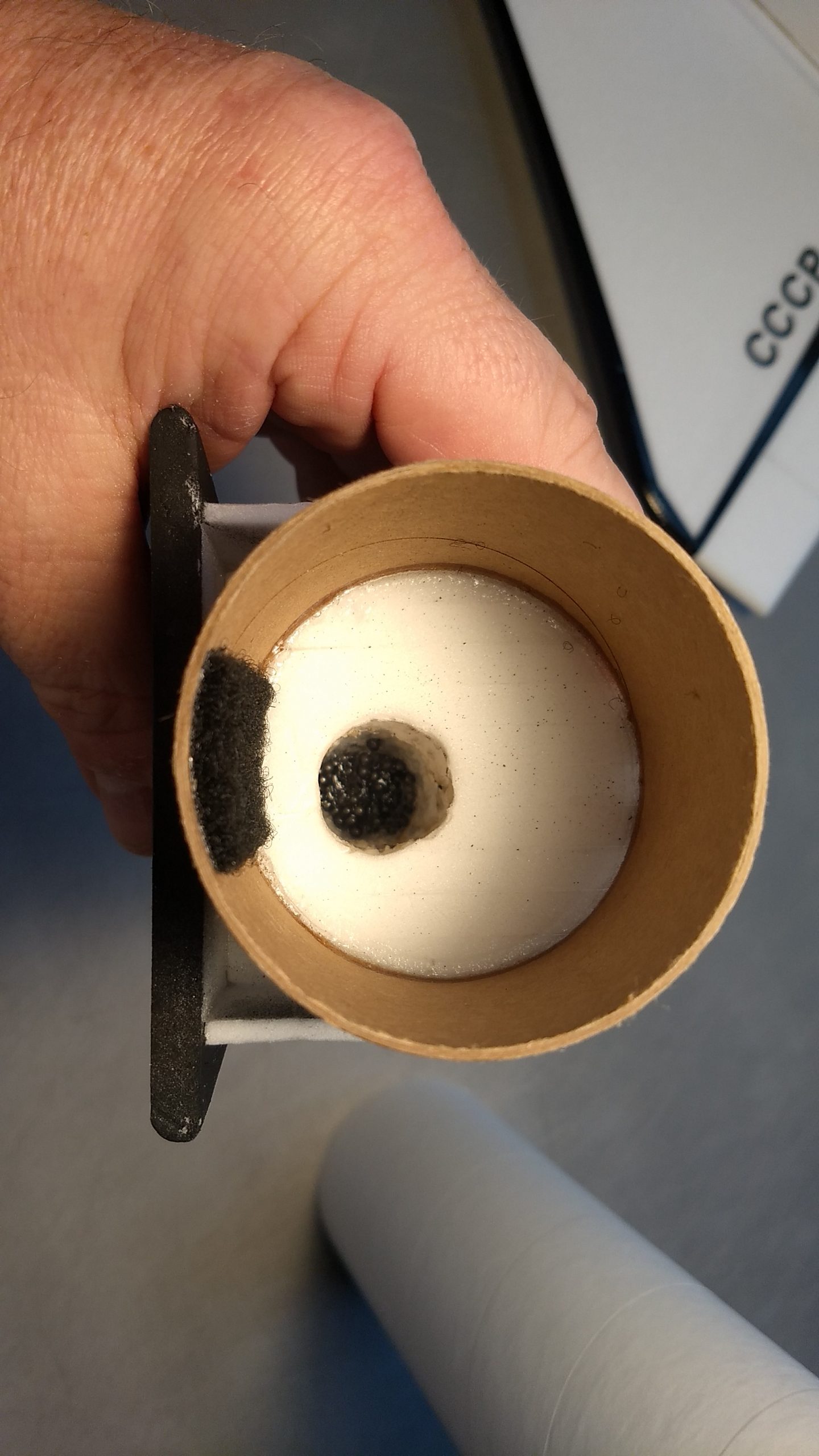

- I then used a hot soldering iron to melt a 1/2″ by 1.5″ long hole in the center of the inside of the nose section so that the nose weight can be more forward and require less weight. You can use a knife or drill to do the same thing. Be careful not to go through the nose cone completely.

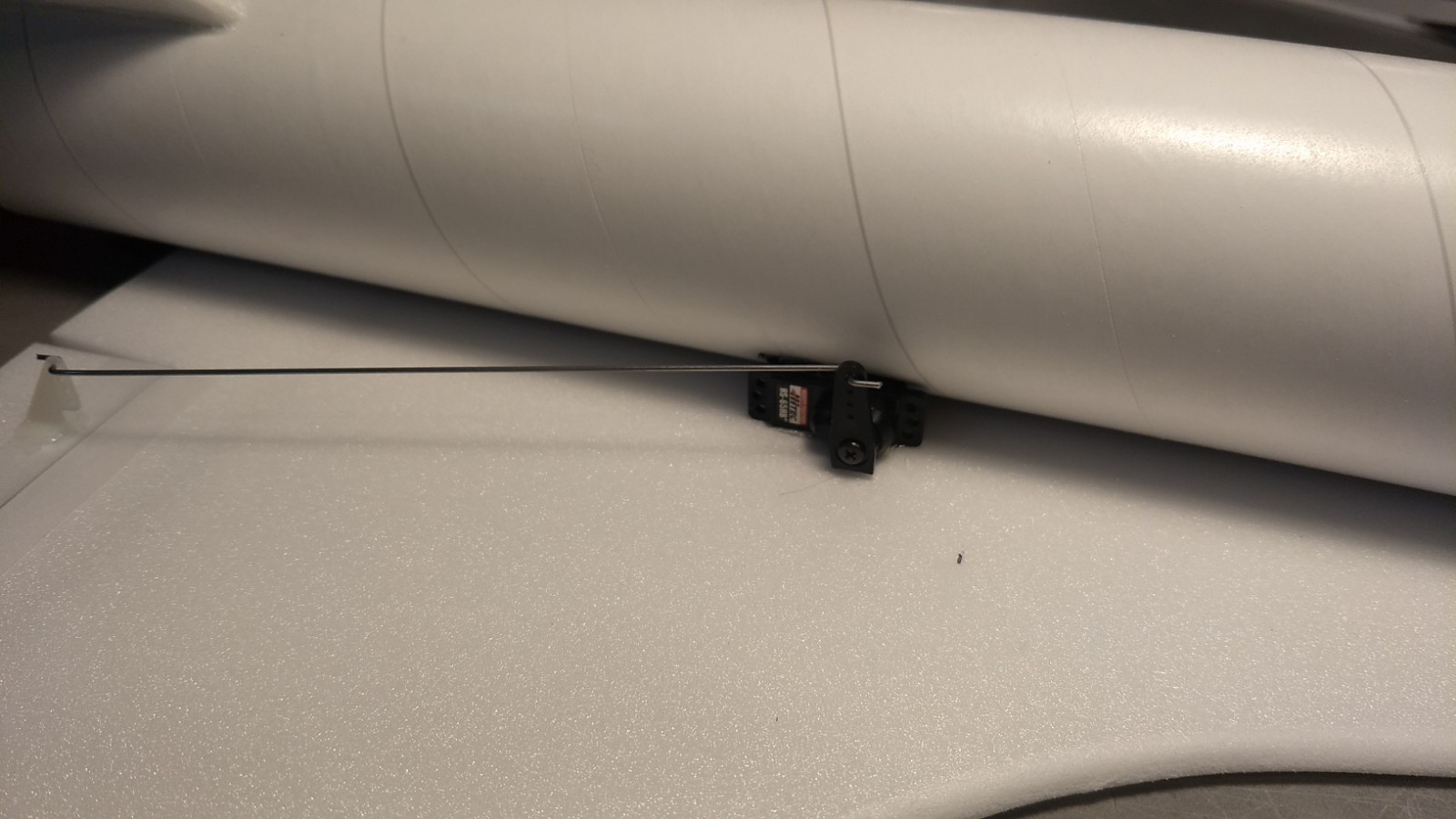

- Measure 4″ from the rear of the body tube and 1 5/16″ from the front of the body tube and make a small hole through the bottom of the wing at these two points using a small screwdriver or round tool. It should pass into the body tube via the pre-punched holes.

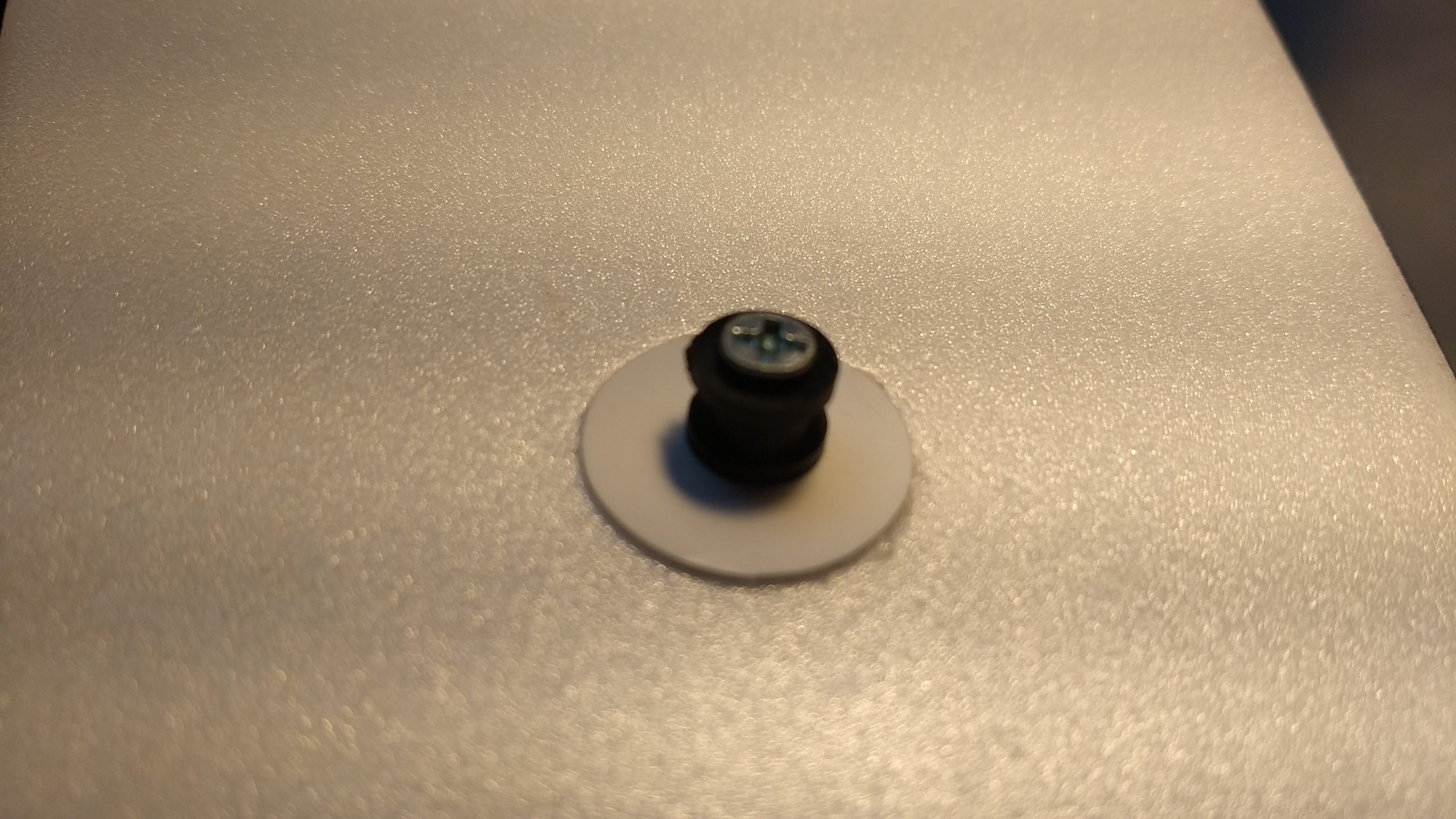

- Glue one of the plastic disks in place over each hole on the bottom of the wing.

- Install both the front and rear rail buttons at this time. Insert a t-nut from the inside of the body tube and install the rail button and screw on the bottom of the wing and secure it to the t-nut. If your kit came with a short and long screws, use the longer screws. Don’t over tighten or you will crush the wing foam.

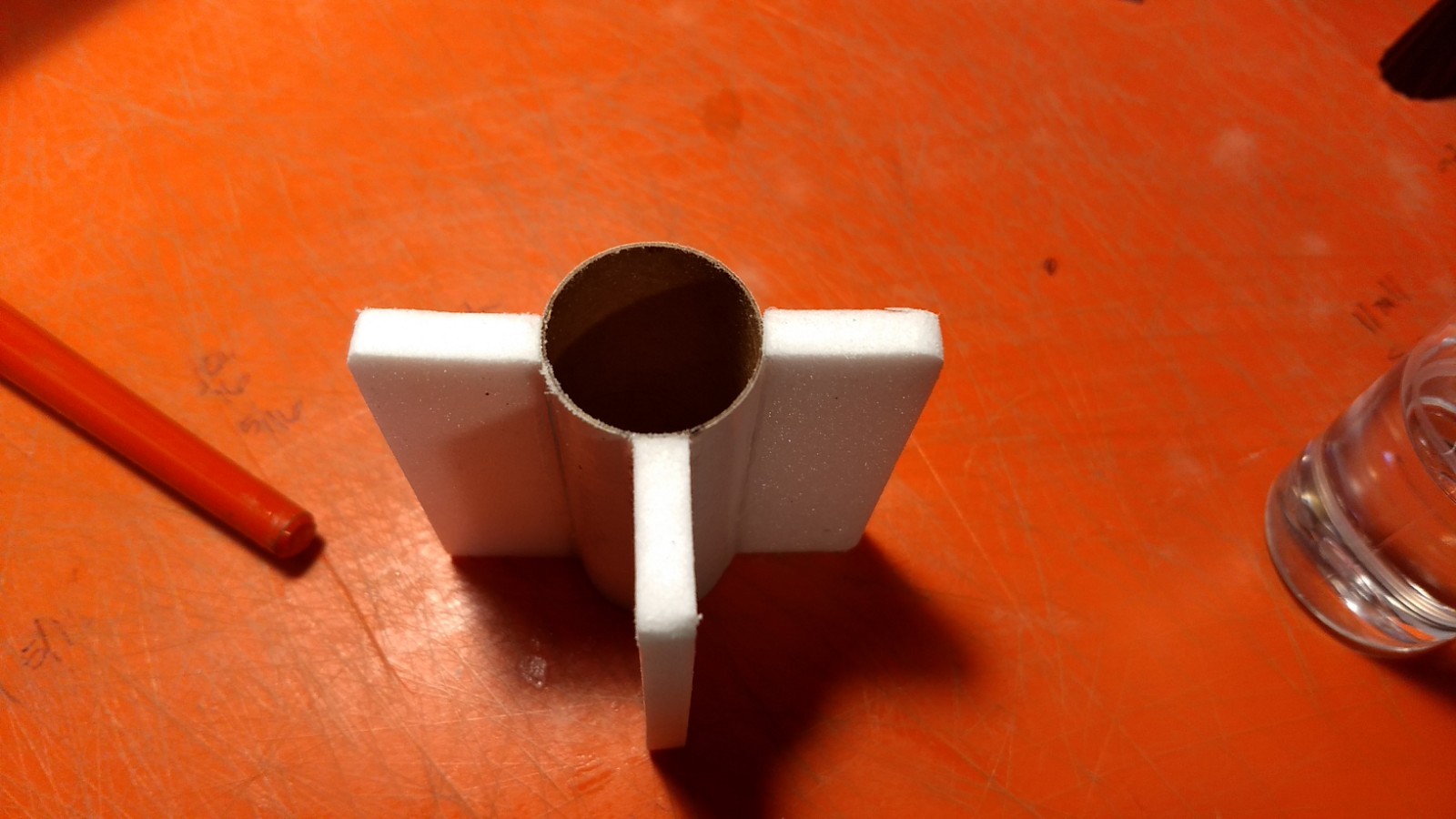

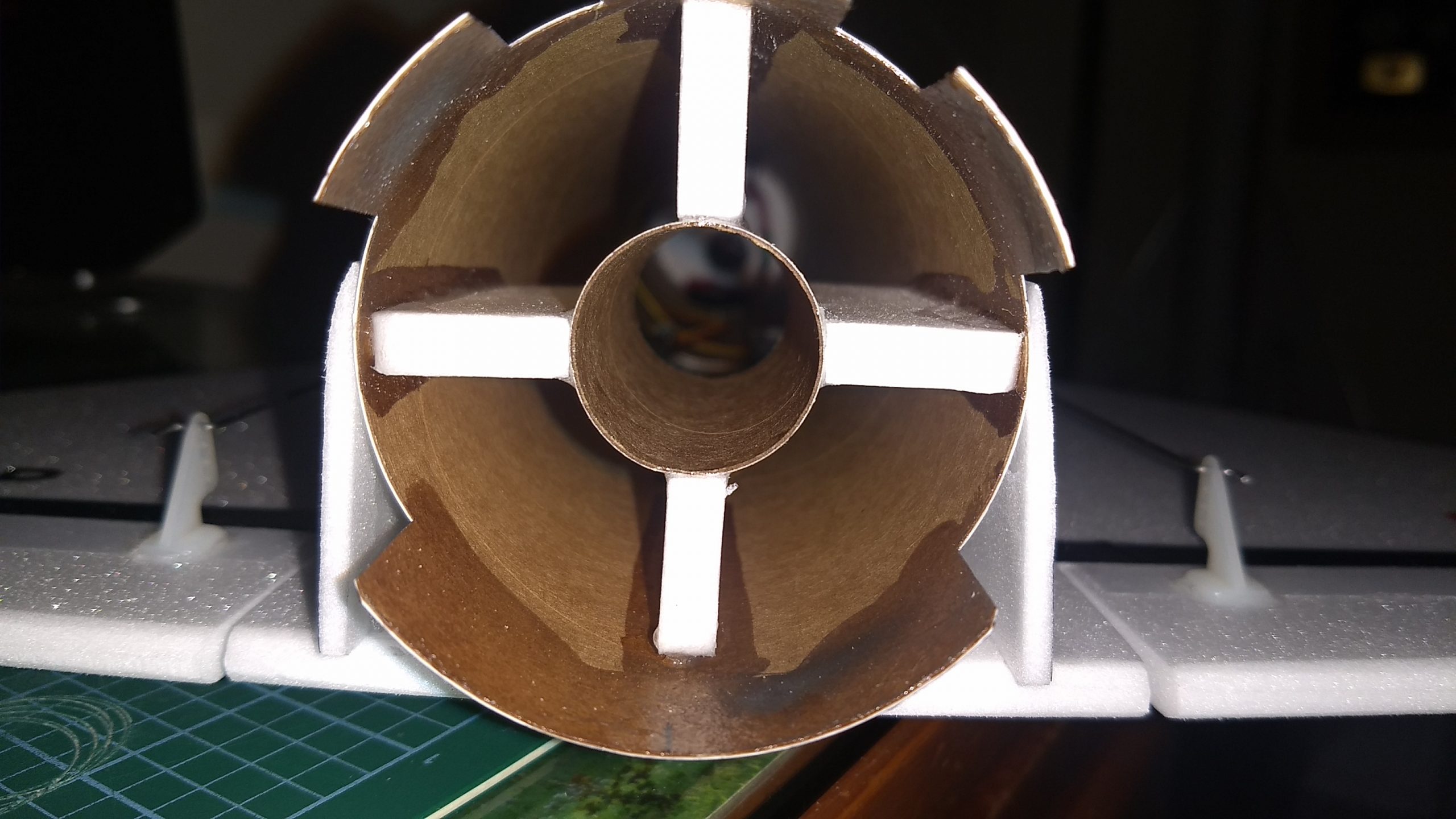

- Glue the 2.75″ long foam strips on the the pre-marked motor tube lines.

- If you do not use a reloadable motor you can glue the included thrust ring into the front of the motor tube. You will friction fit the motor for flight with a small bit of masking tape to make sure it doesn’t fall out, the reloadable motor will stop on the rear closure and you don’t need the thrust ring in that case.

- Test fit the motor mount into the rear of the body tube. Make sure it fits, or sand the foam tabs lightly. Glue the motor tube in place flush with the vertical stab tab at the rear, it will be inset about 3/4″.

- I can only recommend testors/model master enamel spray or Krylon short cuts small rattle can enamel paintat this time, others I’ve tried damage the foam surface. I recommend flat colors as they dry faster and the surface imperfections of foam aren’t as noticable. I left the body tube and top of the wing bare(no paint to save weight) and just masked off and painted the sides/bottom of the wing and nose cone flat black. The tail can be marked with sharpie pen, hand or spray painted after masking as desired. Use the pictures as a rough guide for painting, or look at photos of the Buran for more detail if desired.

- Once you apply the vinyl markings, use a hair dryer on hot to soften the markings and them push them down into the foam surface with your finger. They will really conform and stick down well.

- **Balance the model after painting as it adds weight to the rear.

- Insert your heaviest loaded rocket motor into the motor mount and make sure the battery is installed.

- Support the model at the balance point indicated for boost. I use two pencils with the eraser pointed up and the erasers tapered a bit to a soft point and held in place with a small hand vice on each side of the model. Place the model upside down on the pencil erasers on the balance point indicated above. Use pieces of the included lead weight as far forward into the tip of the nose to balance it as needed. Glue the lead weight in place so it does not shift during flight. Do a little at at time as you get close to avoid using too much weight. Do not try to fly the model too nose or tail heavy. Remember, a nose heavy model flies poorly, a tail heavy model flies once.

- **If using the Boyce Aerospace nose cone:

- you will not use the coupler, 1″ body tube ring, 11 nose profiles or the front nose section.

- Omit steps 4-12, 29 and 30

- After step 3, insert the nose cone into the body tube.

- Mark where the rear of the nose cone is on each side of the front of the wing.

- Remove the cone and cut the left and right chine sections of the wing so that they taper inward to abut the rear of the nose cone on the marks you just made.

- Proceed to step 13.

- The Boyce Space shuttle display nozzles slip into the motor mount and are for display only.

- **If building the US version follow these steps.

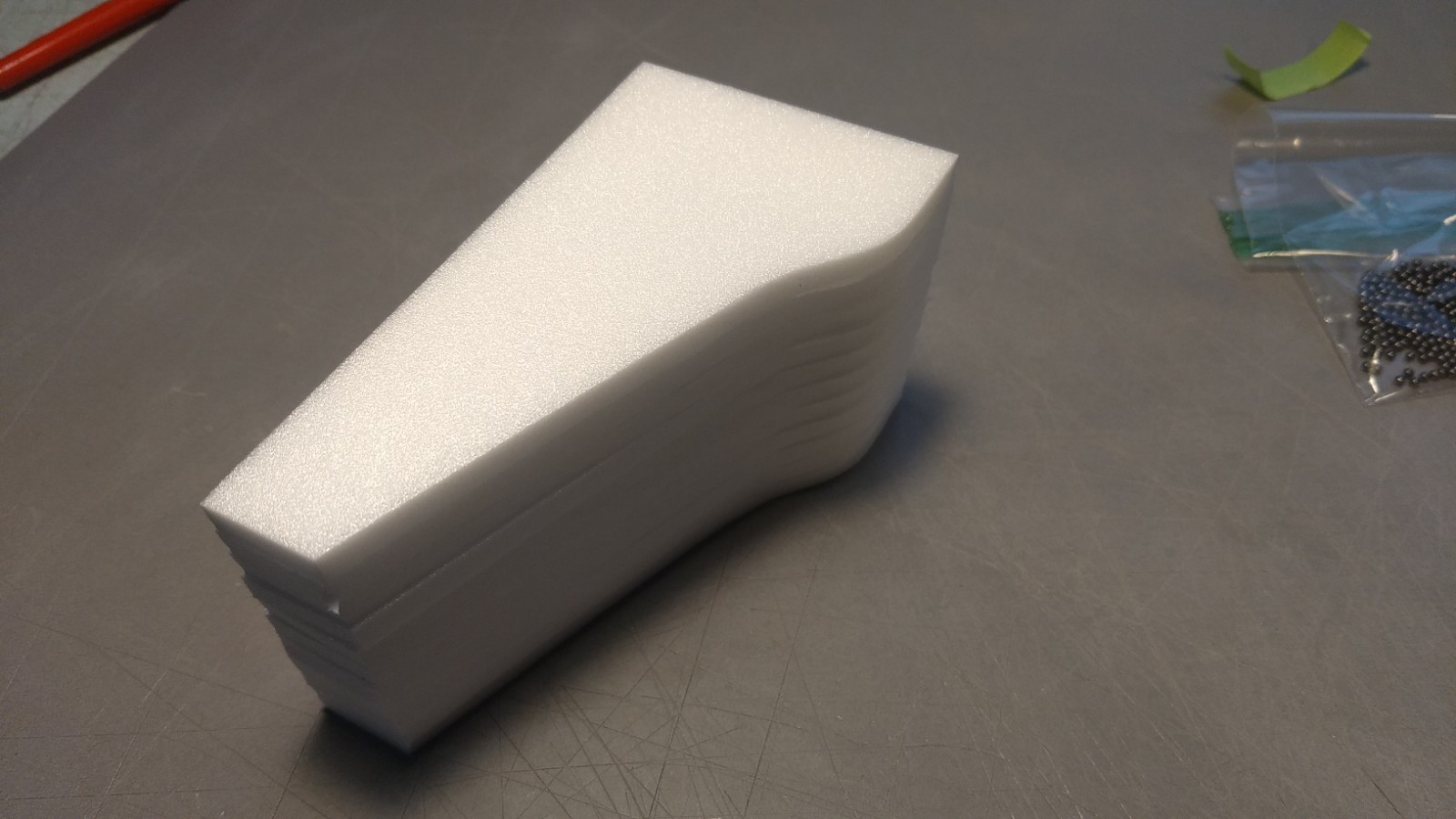

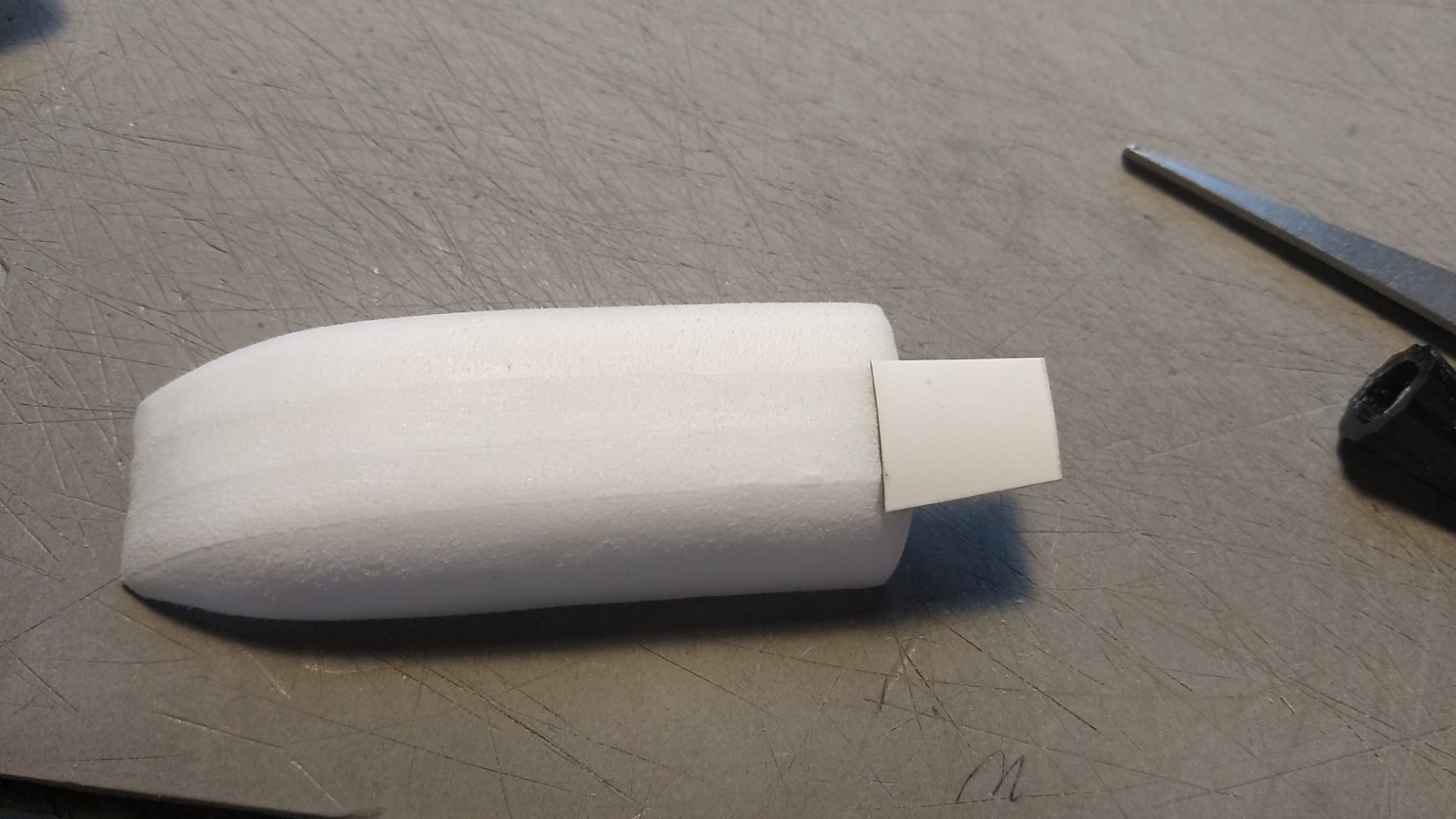

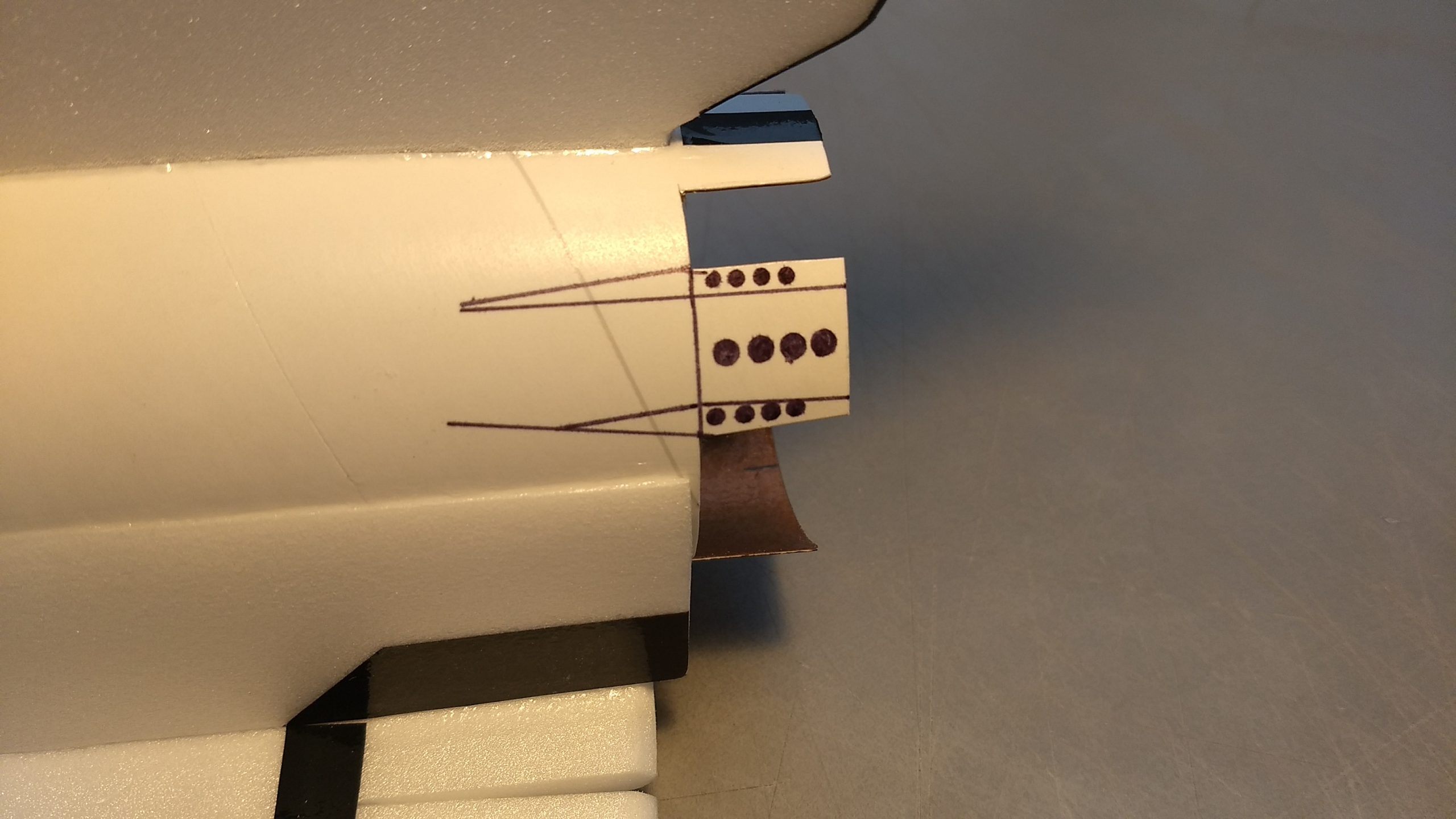

- Stack six of the oms pod pieces and laminate like you did the nose section, repeat with the other five so you have two sets.

- Sand the rear and bottom flat then radius the corners and taper the front as shown in the photo, use 320 grit paper and xacto to shape them.

- Wrap some 220 grit paper onto the top of the body tube and gently sand the bottom of each oms pod till it contours to the body tube shape.

- Cut the rear Buran oms piece from the rear of the body tube and glue to the rear of each US shuttle oms pod. You can use a piece of the spare piece of foam included as a backing to support the cardboard.

- Attach each oms pod to the rear sides of the shuttle.

Flying: See the General Instruction link at the top for flying instructions. Be ready on the first few flights to keep the model straight till you have the trims set perfectly for boost and glide.

- Kit parts

- Glue the taped wing joint and lay flat to dry

- Glue the body tube to the wing with the front of the tube even with the cut forward end of the wing, aligned with the center of the wing and alignment line. Note the body tube shown has rear cutouts that were for the Buran version, the US shuttle won’t have these extra cutouts.

- Glue in the vertical stab. Note the body tube shown has rear cutouts that were for the Buran version, the US shuttle won’t have these extra cutouts.

- Glue short body tube onto coupler flush with one end, have the arrow mark pointing to the rear of the coupler to align with the body tube.

- If your kit came with two tubes and a coupler, join the two body tubes using the coupler keeping the arrow marks aligned.

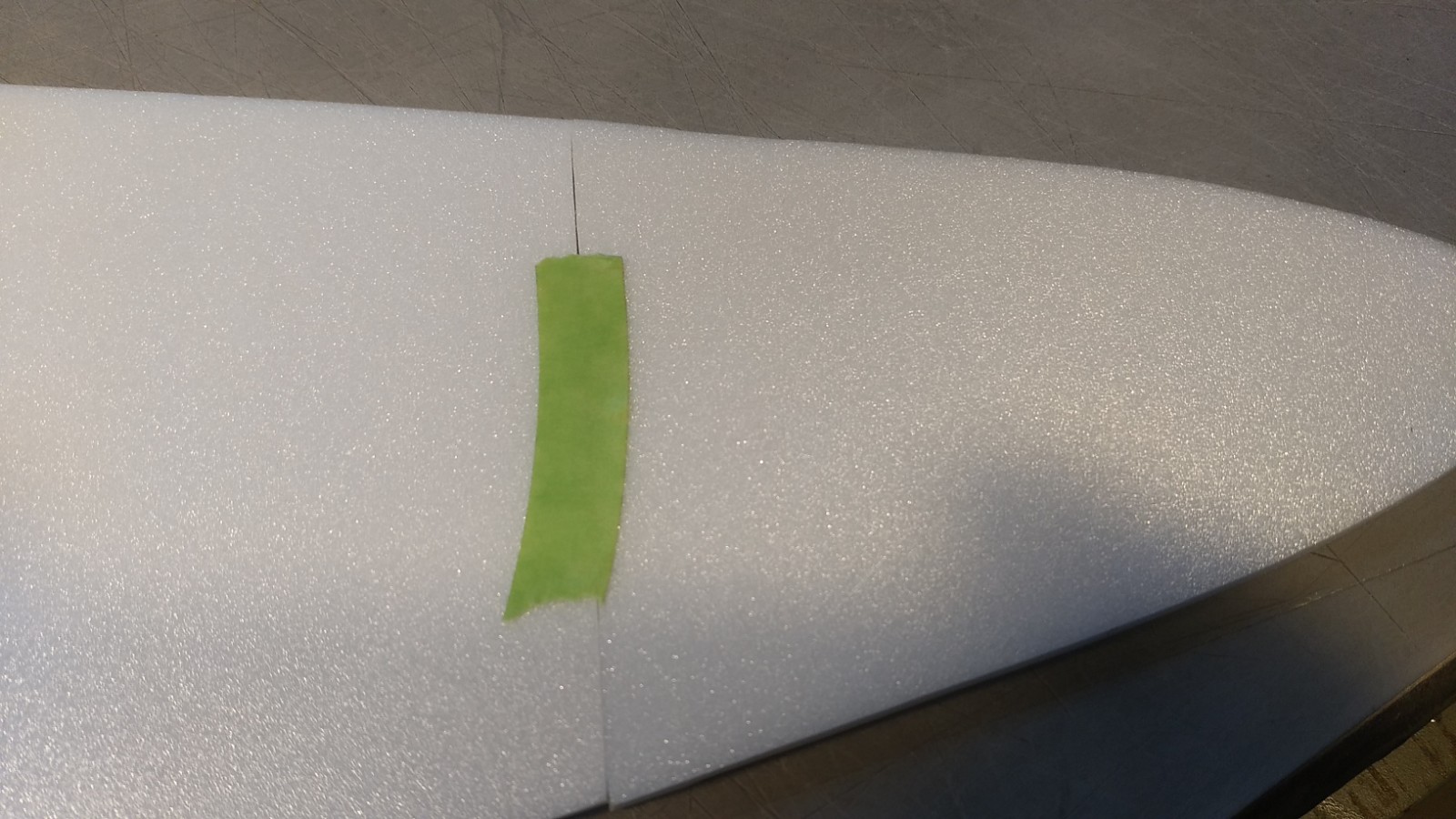

- Temporarily tape the forward wing section to the rear on the bottom for mounting the cockpit pieces.

- Stack and laminate the 11 cockpit sections

- Tack glue the forward body tube piece to the front lower wing section, then glue the cockpit stack to the forward wing and to the the coupler keeping an equal amount of the cockpit stack on each side of the body tube.

- Another view of the cockpit stack glued to the coupler with equal overhang on both sides.

- Fit and glue the short side plate on both sides of the cockpit nose section.

- Glue the control horn into the top of each control surface, note the pushrod will angle inward toward the model.

- Apply glue on the prongs on the bottom of each horn.

- Measure then cut a pocket for each servo on each side.

- Test fit then glue a servo into the pocket against the wing keeping the control surface neutral.

- Taper the top of each side plate to blend it into the body tube then cut out each side plate to clear the servo arm and wire and then glue the side plate to the wing and fuselage, the front should be even with the front of the main body tube.

- Receiver and battery connected out the front of the body tube. Power up the radio and adjust control throws and glide/boost settings.

- Cockpit sanded to shape.

- Use a soldering iron or drill to make a 1.5-2″ long hole in the lower part of the nose cone for adding nose weight. Secure the battery into the bottom of the coupler. Receiver may be mounted inside the top of the coupler or inside the body tube at the top.

- Poke a hole into the front and rear of the wing in line with the pre-punched body tube holes, Glue plastic reinforcing disk onto bottom of front and rear of wing and install rail buttons.

- Glue plastic reinforcing disk onto bottom rear of wing and install rail buttons.

- Glue the three motor strips onto the motor tube as shown.

- Motor mount installed

- Airframe complete ready for painting/decals.

- Optional US shuttle oms pod pieces, stack and glue 6 together and repeat for other side.

- Sand the shape round and taper the front as shown.

- wrap 220-320 sandpaper around the body tube and gently sand the bottom of the oms pod till it contours to the body tube shape.

- Radius sanded into the oms pod then glue to the rear of each side of the shuttle

- Trim the Buran oms piece from the rear of the body tube and glue to the rear of each oms pod

- Mount each oms pod to the model.

- Buran Markings

- US Shuttle Markings

- Example of Stickershock markings for both US and Buran versions

- Completed Buran Left side

- Completed Buran Right side

- Buran OMS pod detail drawn onto the body tube with sharpie pen.

- Completed model ready for painting

- US Shuttle right side

- Completed US shuttle left side.

- Boyce Aerospace Shuttle Nose cone and Shuttle display nozzles

- Shuttle display nozzles installed.

- Boyce Nose cone fitted to Buran kit