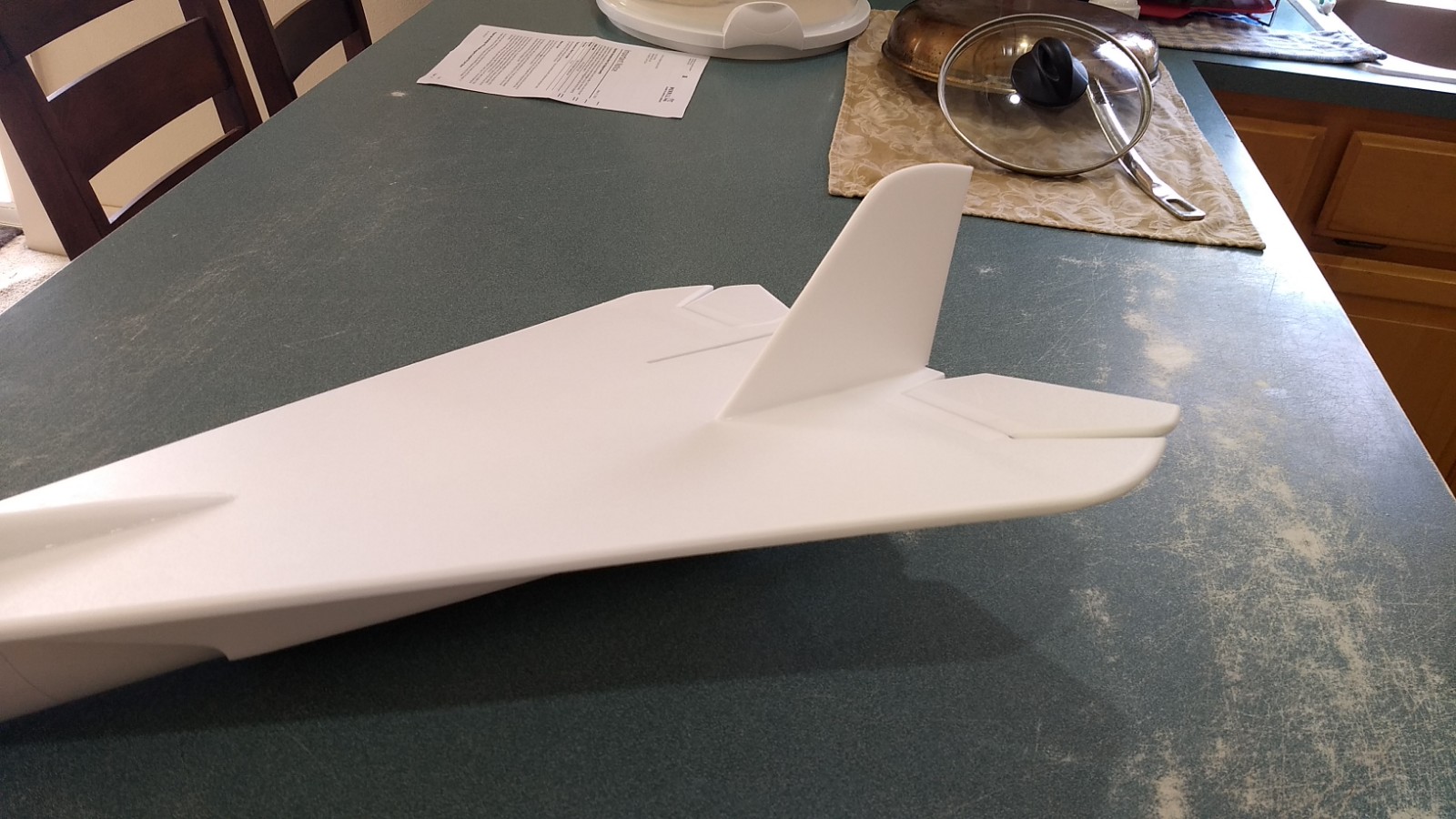

The F-14 Tomcat RC Rocket glider kit is based on the famous Grumman Carrier based fighter jet. It features a high mounted wing with spar pre-installed, a plastic nose cone, 2.6″ white tubing for the body and depron wing and tail surfaces. Wing elevons are pre-hinged. The body tube end is pre-cut at an angle and the rail buttons holes are are pre-punched. You will need two 10 gram type servos, a receiver, and a small 500mah single cell lipo battery. You will need a transmitter with delta or elevon mixing. Specs: 31″ length, 19″ wingspan, 10 oz rtf, for 24mm E-6 single use or reloadable motors. Kit includes 5 pages of marking guides for the panel lines and cockpit decals.

This kit is designed to be simple to build and be light with good glide performance. I did not add a swing wing feature because at this size it will add too much weight, reduce strength and make it much more complex to build and kit. Similarly the intakes are just profiles to give the right look and add strength but not drag or reduce the wing area.

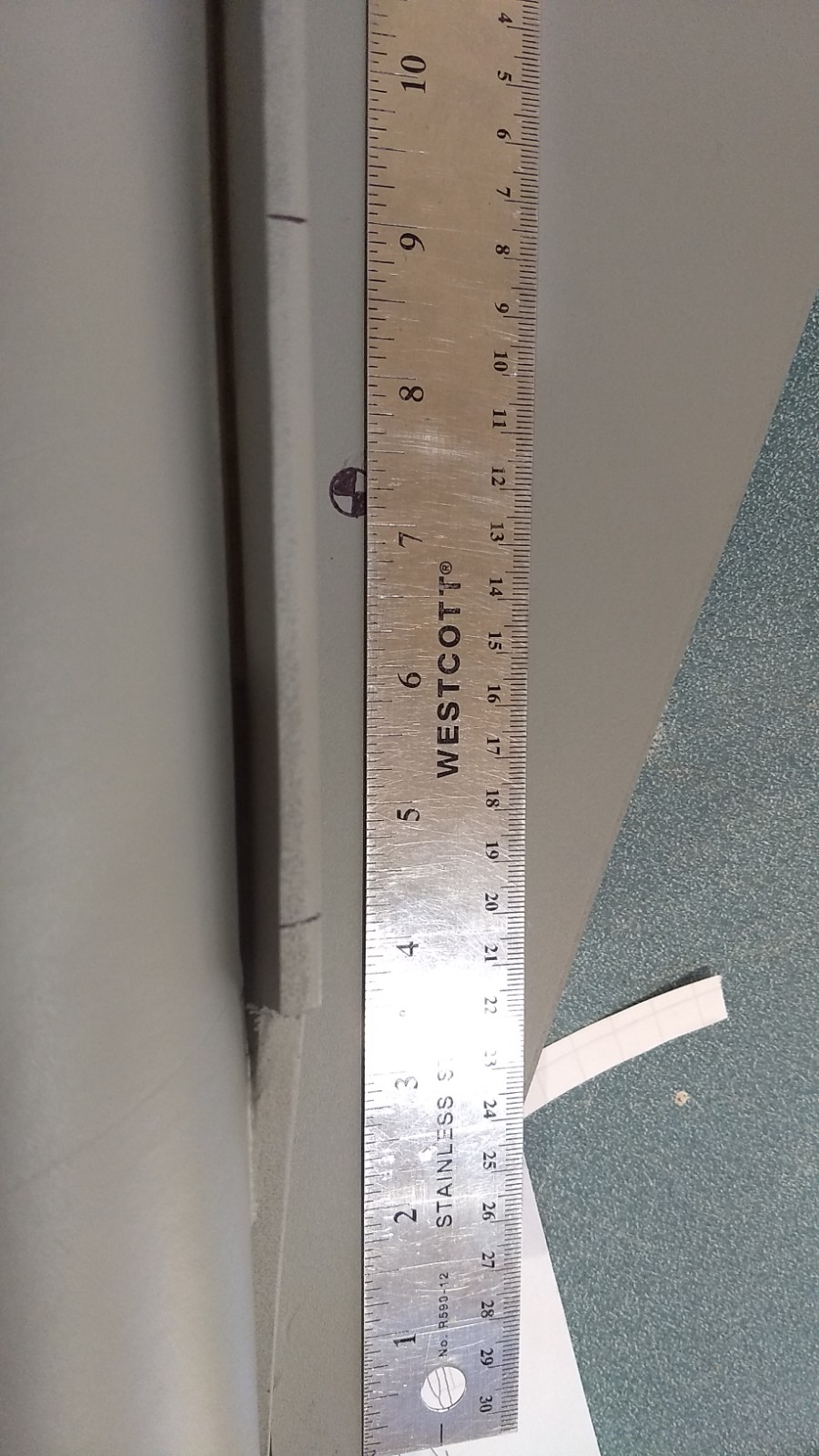

CG location for rocket flight with battery and loaded motor installed: 7.25″ to the rear of the leading edge of the wing where it hits the fuselage.

Please refer to the General Information Link above then read the instructions completely before starting assembly. The assembly photos are for general reference but may not include every step in the instructions. If you want hardcopy to work from, all you have to do is click/drag/select and copy all of the text below, open word and paste with “keep original format” and it looks exactly like it does online then you can print it.

One note, the kit includes patterns for the panel lines. If you want to order the decals from sticker shock you can order them: HERE

Unpacking your kit:

The kits are packed to protect them in shipping, but the contents are fragile so unpack carefully. Carefully cut the tape holding the tubes in the box, then unwrap/lightly cut the plastic wrap to free the tubes, the spar may be packed in the tubes and the baggie with the little parts and nose cone will be in the tubes as well. Carefully cut the tape holding the cardboard wing protector in the box and carefully remove it, don’t pull hard or bend it. Then carefully cut the tape holding the cardboard top piece to the bottom. There may be some sticky tape holding the cardboard to the bottom cardboard piece, carefully peel it being sure not to bend anything. Once the top cardboard is free you can see the foam wing/tail parts, there are little fragile pieces in here, so unwrap carefully. It may be best to use an exacto to lightly cut the plastic wrap and carefully remove it without cutting into the foam. Make sure everything is free before you remove the pieces to avoid breaking anything. Kits contain one or two scrap pieces for repairs if you damage anything in construction or flight, just cut and patch in a spare piece of the foam if needed using foam safe CA+.

Welcome to the world of rocket boosted radio control gliders. This is not a model for a novice RC pilot, but anyone who is comfortable with RC flying of a medium speed model should be fine. Read through the instructions, look at the photos and be sure you understand the step before commiting to cutting or glue.

F-14 Tomcat Rocket glider instructions

Identify all pieces, the kit should contain:

1 wing taped together

1 Nose Cone

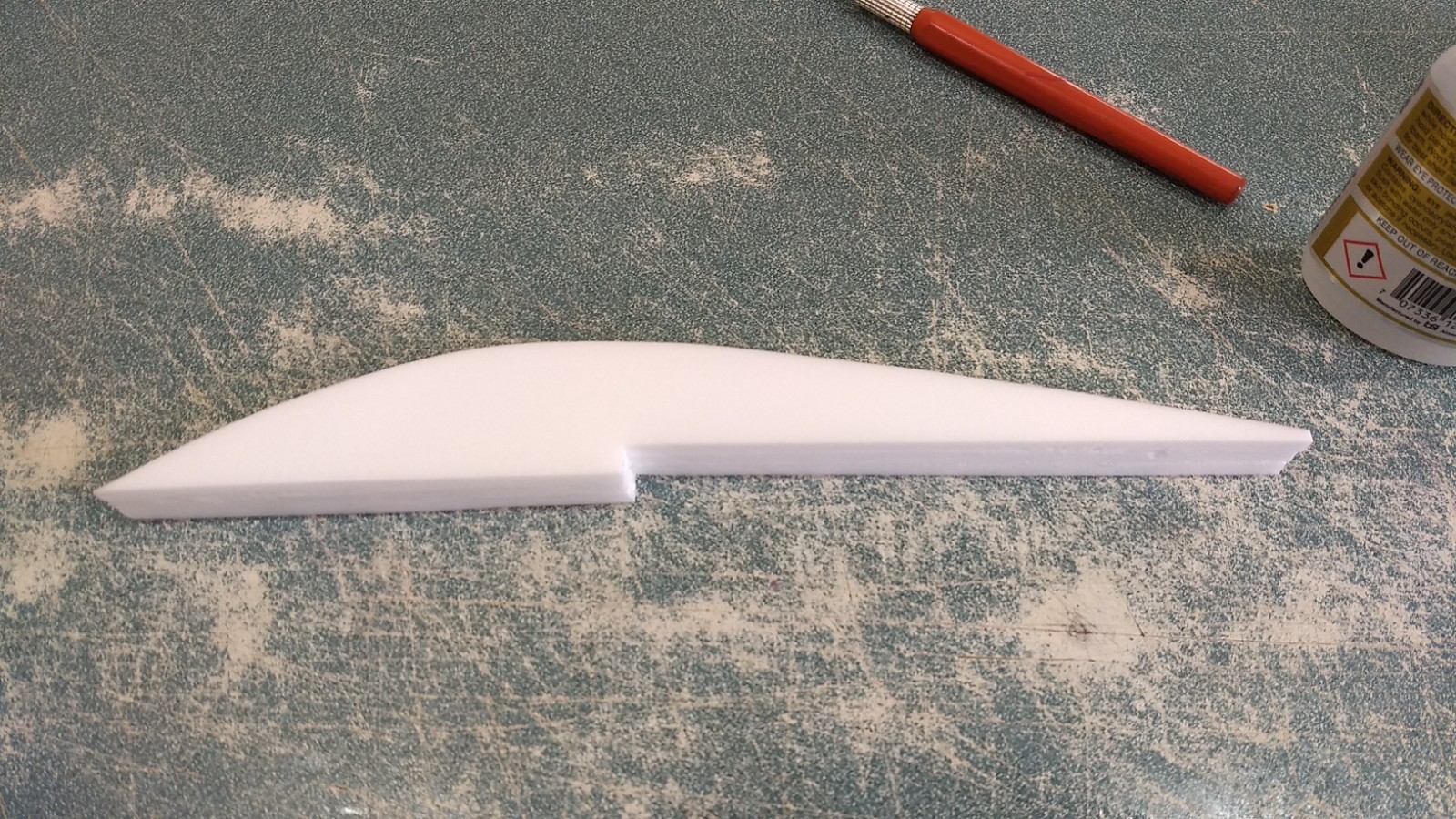

2 vertical stabilizers

2 control horns w/pushrods

2 2.75″ beveled motor tube supports

1 Body Tube

Motor mount

2 engine intake side plates.

3 cockpit pieces.

Velcro(for battery and rx/bec attachment)

Lead weight

Spare depron

Notes before starting:

Reference to glue, CA, or CA+ means foam safe CA+, normal CA+ will melt the foam! Normally you need to use accelerator to get the CA to set on the foam since there is nothing for it to soak into and activate.

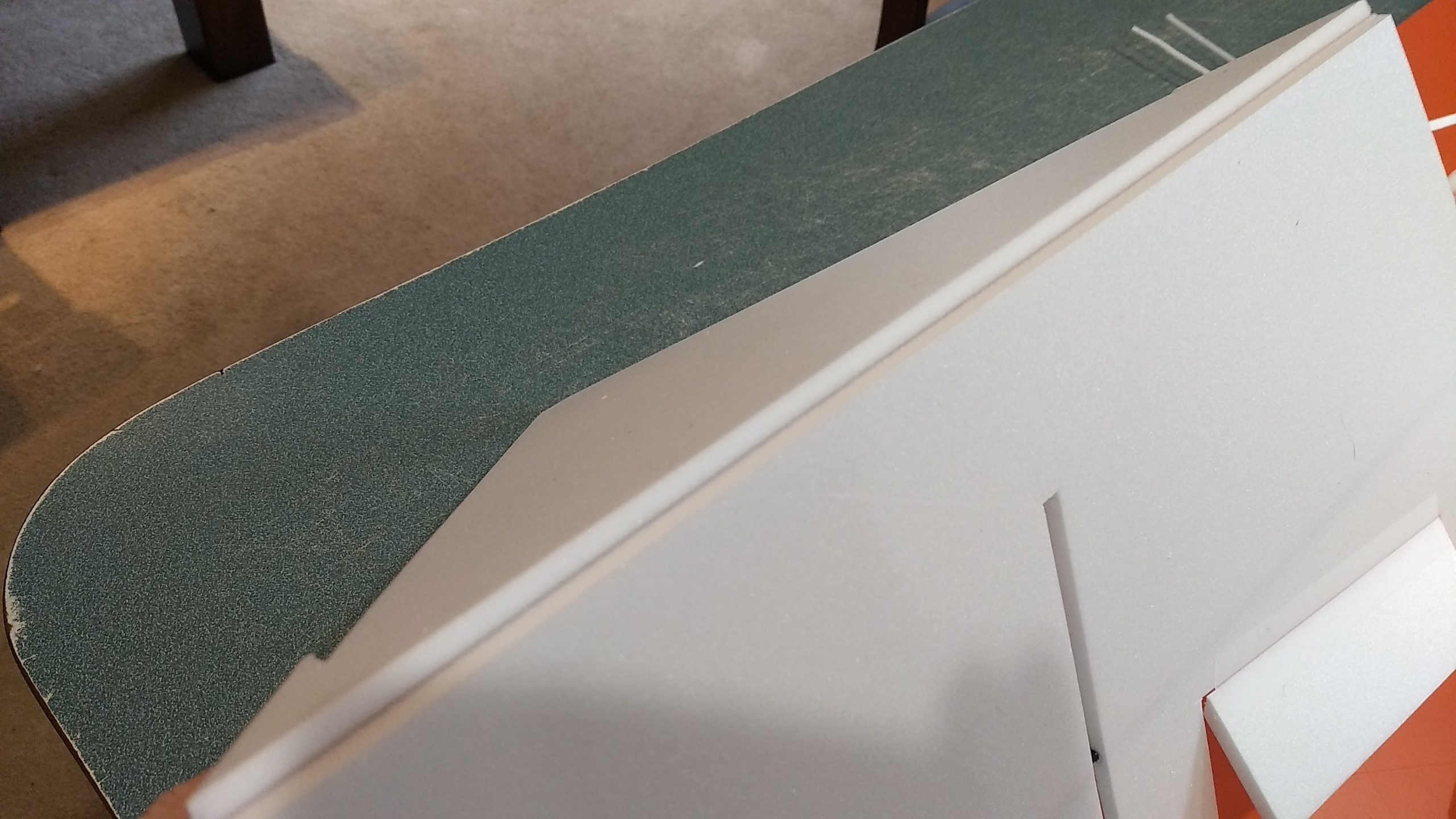

You may use 320 grit sandpaper and a sanding block to slightly round the edges of the foam if you prefer that look. It will not markedly impact the flight performance either way. Be very careful and use a VERY light touch, it is very easy to catch the foam on the edge of the paper and tear the foam. Do any sanding before assembly.

Epoxy is not needed in this model. Weight is critical and the model is designed for the thrust and flight loads.

Assembly:

- If your kit came with a motor block ring, glue it to the front of the motor tube at this time. Glue the motor tube onto the inside top of the body tube on the line marked, the rear end of the tube will be about 1.75″ from the rear of the tube. Once set, glue a foam reinforcing strip on either side of the motor tube. I recommend that you can apply a coating of CA to the body tube to the rear of the motor tube to make sure it is protected. See picture for clarification.

- Install the two rail buttons in their respective holes.

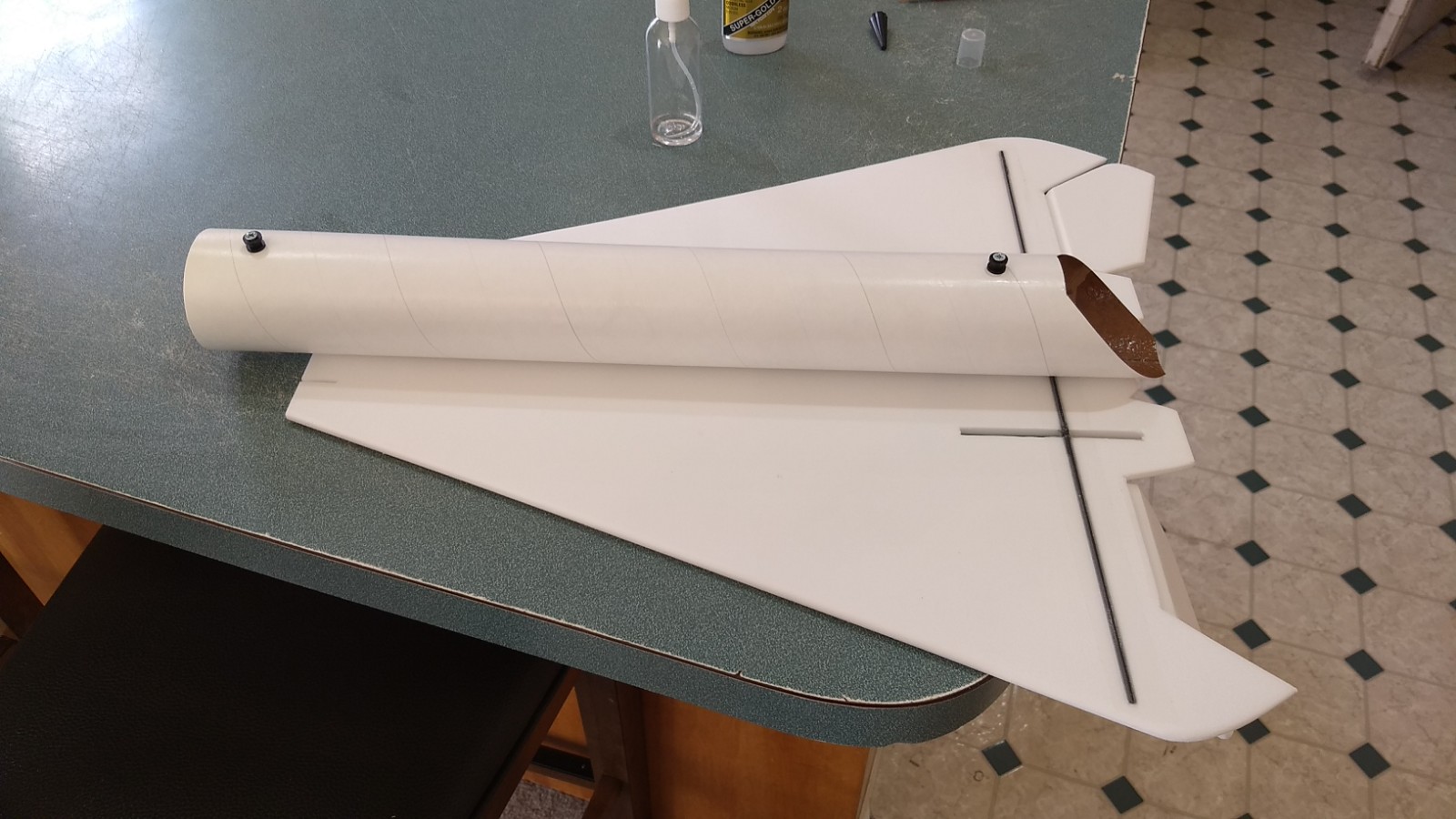

- Unfold the wing and apply glue to the wing at the taped joint and set it on a flat surface to dry face up. Then flip the wing over, the bottom of the wing will have the spar visible.

- Lightly sand the fuselage wing line and apply a squiggle of glue about 1/2 wide to the body tube wing line.

- Lay the wing on the body tube on the alignment mark using the front center of the wing and the rear line on the alignment line as a guide. The front of the wing should start 2″ to the rear of the front of the body tube. The rear of the body tube will stick past the rear of the wing about 1/2 to 5/8″. Flip the wing and body over onto a table top, making sure the wing does not move and make sure the body tube is centered. You can measure from the wingtip to the body tube side on each side to make sure it is centered. Make sure it is set before continuing.

- Glue a motor intake to each side of the body tube and onto the wing.

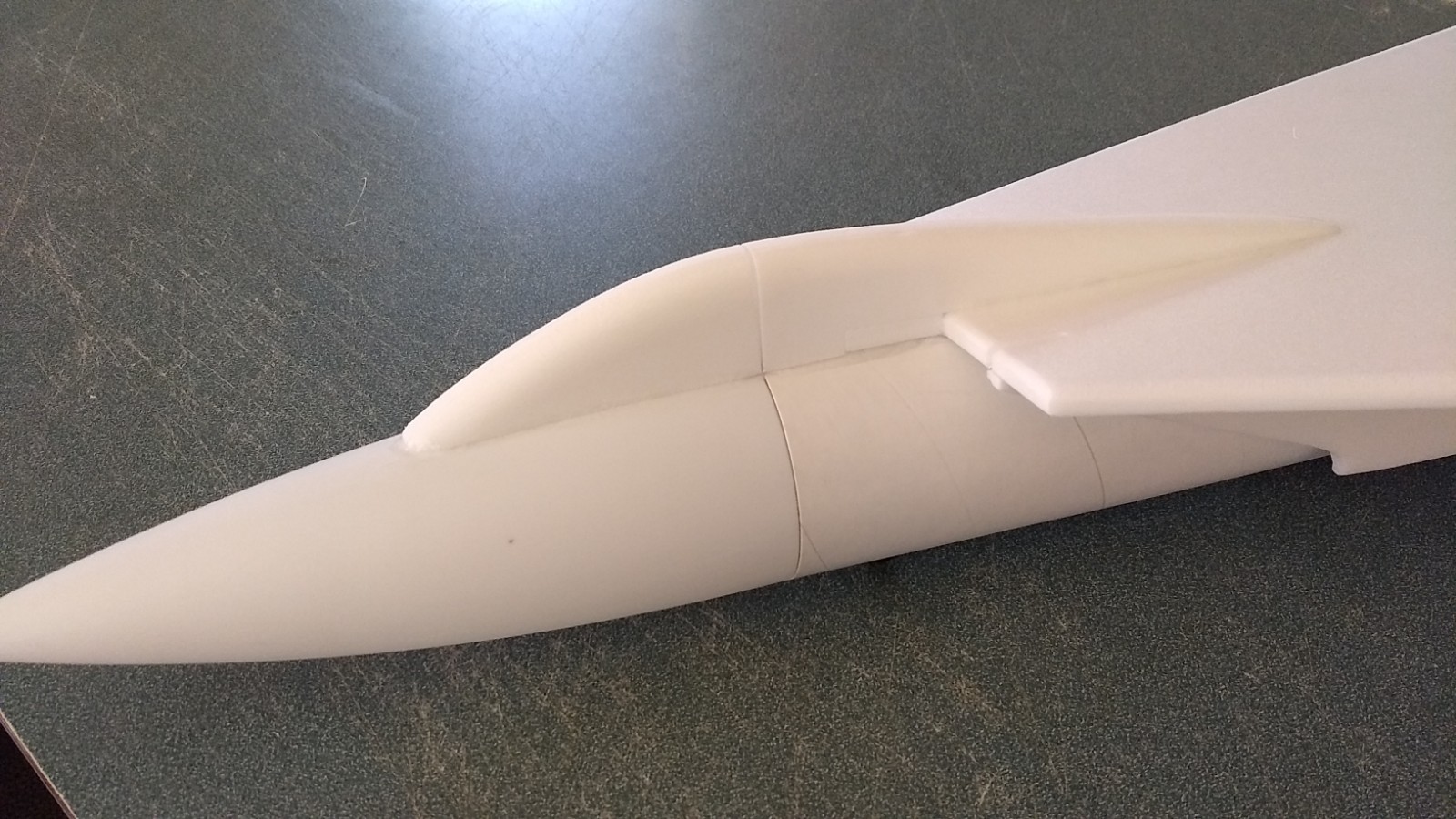

- Glue the 3 cockpit pieces together.

- At this point shape the cockpit as per the pictures. When done lay it against the front of the wing. Tape the nose cone in place, then glue the cockpit onto the top of the wing and the top of the nose cone, make sure not to glue the nose cone to the body tube! You may need to press and hold the front and rear of the cockpit till they set. Apply a fillet of glue once set to help fill in any gaps.

- Once dry, cut the cockpit through at the nose cone joint so that they can separate.

- Test fit the vertical tails into their slots and make sure they fit. Glue into the slot using foam safe CA+ making sure the tails are perpendicular to the wing and is straight.

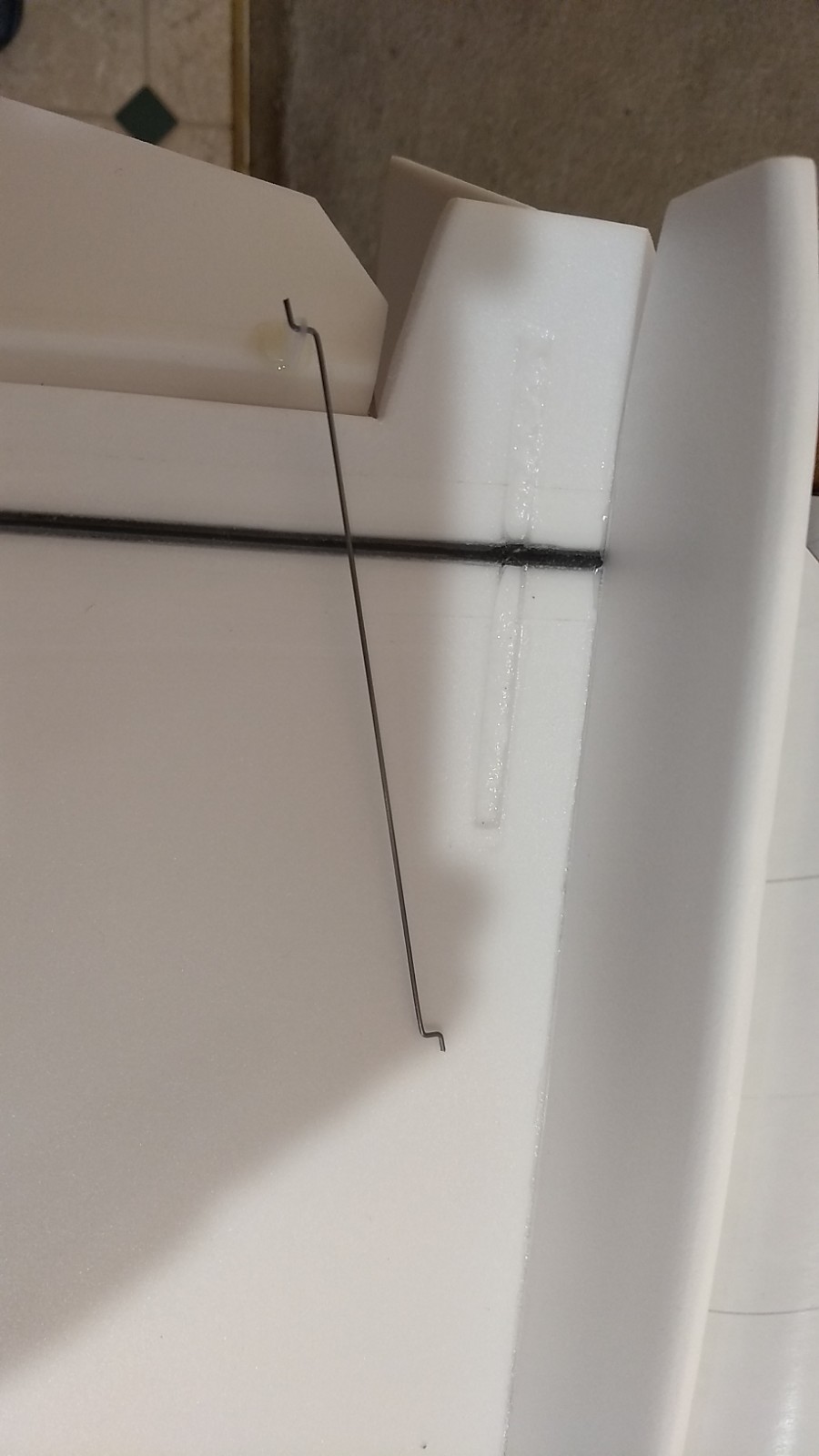

- Glue each control horn in place on the bottom of the control surface using the pre made holes. If your model does not have the pre made holes, you can make them with a round toothpick, the horn should glue in to the bottom of the surface 1″ out toward the wingtip from the inboard end of the hinged surface. The control horn holes should be pointing toward the front of the model. Repeat on the other side.

- Put some CA on the top of the control surface where the horn prongs stick through, this locks it in place

The basic construction is now complete.

Radio Installation

Note: Your radio needs to be configured for Delta mixing, this means that the servo arms will move the same direction during elevator stick movement and opposite for aileron stick movement. Connect your servos to the receiver one in the aileron connection and one on the elevator connection and apply power. Use a servo arm at least 9/16” long and with holes small enough that there won’t be slop with the pushrod wire when installed. I use the hole furthest out on the servo arm, to maximize movement. On some servos there are a long two-ended servo arm, you can trim off one end if needed to get sufficient length. Zero out any trim settings on the transmitter.

- Connect a servo to each pushrod. If the pushrod is too tight, you can use twist an exacto knife in the servo arm hole to make it larger, but be careful and do not make it too large. Once connected, tape each servo in place so that the control surfaces are centered. Flip the model right side up and look at it from the rear. Moving the transmitter stick back(up elevator) should move both elevons up. Moving the transmitter stick to the right should move the right elevon up and the left elevon down. If you can’t get the servo reversing to give you the right polarity try swapping aileron/elevator inputs to the receiver or turning the servos over and swapping the servo arms to the other side of the output shaft. If that is correct, continue.

- Flip the model upside down and supported. The servos may be attached to the model using double back servo mounting tape(not included) or by directly gluing the servo to the wing with CA+ or a small amount of epoxy. Double back servo tape can loosen over time and with exposure to heat, I prefer to glue the servo in place. I marked where my servos would go then cutout the side plate to fit the servo, this allows you to recess the servo slightly and also cut a slot for the servo wire to pass through. Make sure to remove any glue from the side plate when you remove the cutout so that the servo can glue to a flat surface. Cut a slot into the body tube and pass the servo wire through to the front, add a servo extension to reach the front.

- With the radio still on, put a small amount of glue on the servo, being careful not to get any near the output shaft. And set it in place on the model keeping the control surface centered and recessed into the side plate slightly. Do the same to the other side. Make sure the glue is set before continuing. The servo should be near the side of the model.

- Flip the model back right side up. Make sure the control surfaces are centered, use trims if needed. Now measure the control surface movement. Full elevator movement should be 1” in each direction, aileron movement should be 1″ in either direction. Since the model will be nose heavy, extra elevon movement helps to give sufficient authority during glide.

- If you have a flap/elevator mix you can program up elevator to a switch setting. The model needs approximately 3/8″” of up elevon during glide. If you can’t set the up elevator trim to a switch on your radio you’ll have to manually put in boost and glide trim which is hard to do while flying the model. My model needed about 1/8″ of downtrim for straight boost.

- Attach the receiver into the nose cone with provided velcro at the top.

- Attach the flight battery into the nose cone with the rest of the provided velcro.

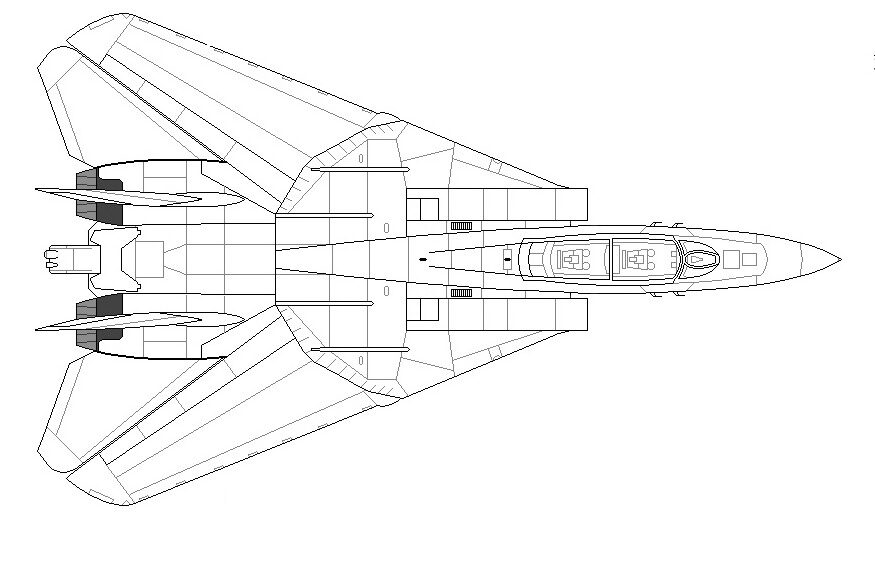

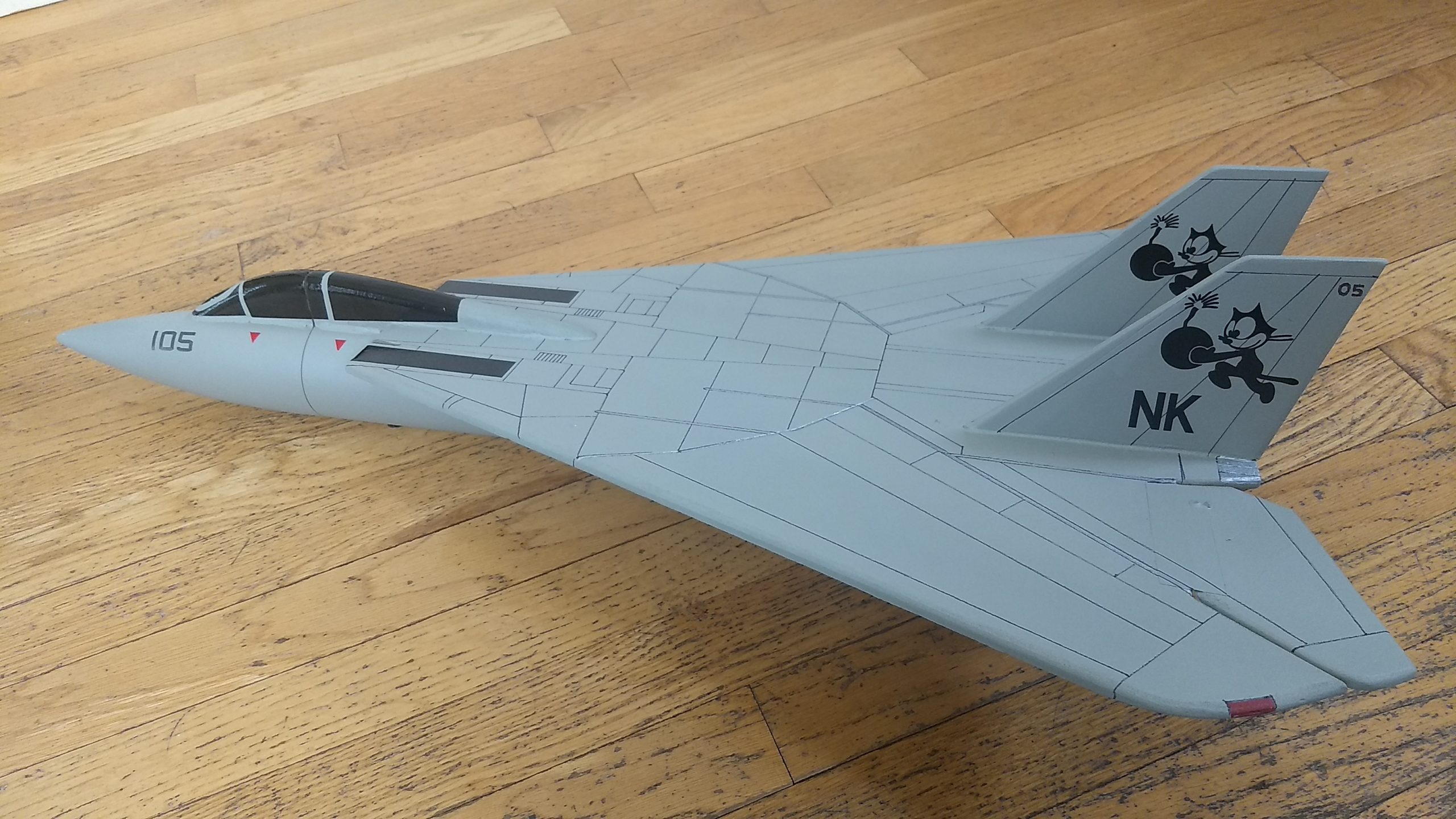

- Finish the model as desired, see general instructions for paint recommendations and warnings. I painted mine with testors spray dark flat aircraft gray. I used a sharpie pen and clear drawing triangles to make panel lines using the guide and it adds a lot to the model and doesn’t take that long. If you purchase the sticker shock decals refer to the pictures for placement. The large black piece of vinyl is to be used with the canopy templates provided with the kit. Simply cut out those templates trace them onto the vinyl and cut them out. I have you do this by hand because it depends on how you round the canopy how they fit and they may need some hand fitting. After application of the vinyl use a hot hair dryer to soften decals and press them in with your thumb to make them set and conform to the model.

- Balance the model after you have painted it as this will add tail weight!

- Insert your heaviest loaded rocket motor into the motor mount and install the flight battery as if you were going to fly it.

- Support the model right side up at the balance point indicated for boost. Glue pieces of the included lead weight in the nose or tail as needed to balance it. Do not try to fly the model with it balancing it behind this point or significantly nose heavy. The adage is, a nose heavy model flies poorly, a tail heavy model flies once.

Flying: See the General Information link at the top for flying instructions. Be ready on the first few flights to keep the model straight till you have the trims set perfectly for boost and glide.

- Kit parts.

- Add the foam reinforcing strips on either side of the motor mount.

- Install rail buttons at front and back in the pre-made holes if they are not installed already.

- glue the taped joint on the wing then lay flat to dry

- glue the fuselage to the wing using the front mark on the fuselage and the longitudinal line on the tube and marks on the wing.

- Checking the alignment of the wing, rail buttons should point straight up.

- Add the left and right side plates with the front of the plate even with the front of the wing.

- Laminate the cockpit pieces

- Round the cockpit and sand the bottom using the the nose cone/body tube and sandpaper.

- Glue the cockpit in place.

- Glue in the two stabilizers.

- Glue in the two control horns/pushrods, note how the pushrod is closest to the body tube and the wire naturally angles inward.

- Add some glue to the top of the horn prongs to lock them in place.

- Completed airframe.

- Cut a notch for each servo and a slot to pass the servo wire through to the front.

- Glue each servo in with the surface centered.

- both servos installed.

- CG location, see written cg location

- Top view for panel line ideas.

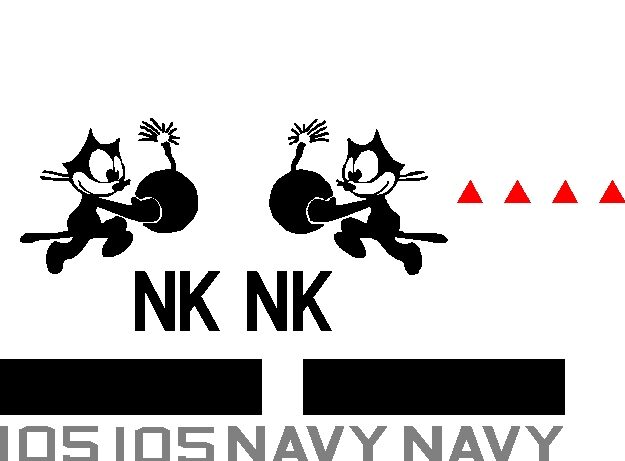

- Stickershock decals

- Completed model showing panel lines

- Completed Model